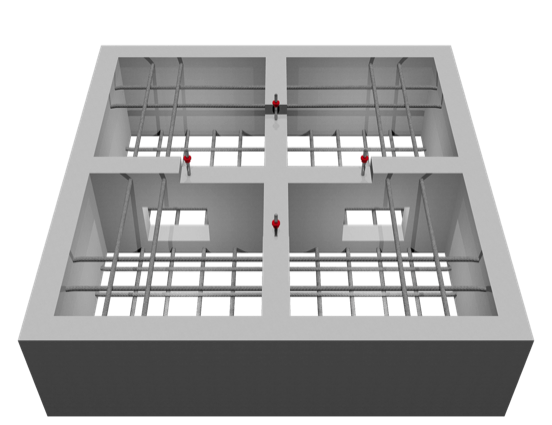

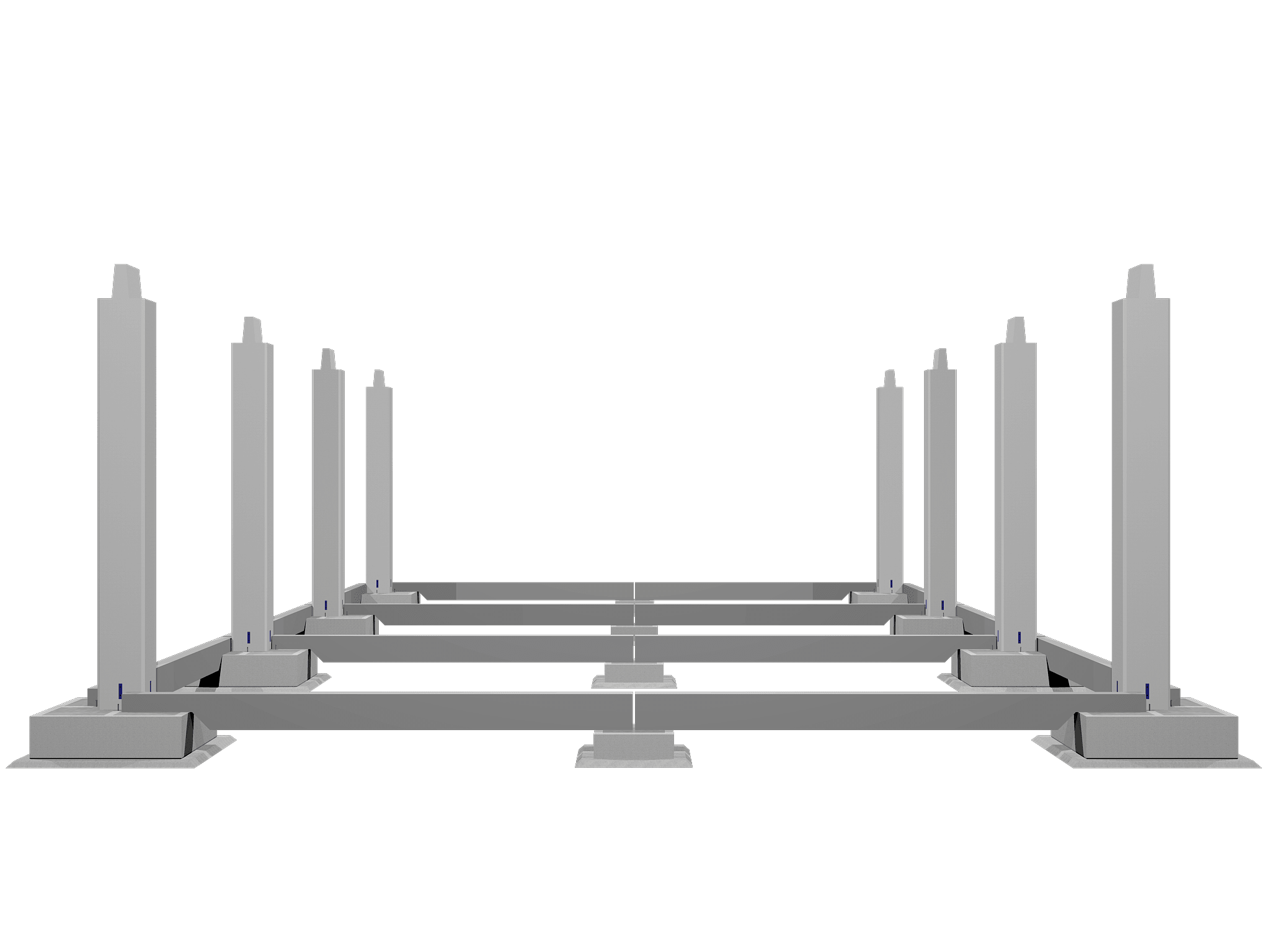

Precast PAD Foundation / Precast Footing

It is the latest advanced in engineered solution, designed to join the precast column to its footing without using concrete pocket or bolted connection. This innovative solution is about saving money, speeding the construction process and improving the assembly precision of the precast column. Our technology lets you have the best connection between column and foundation.

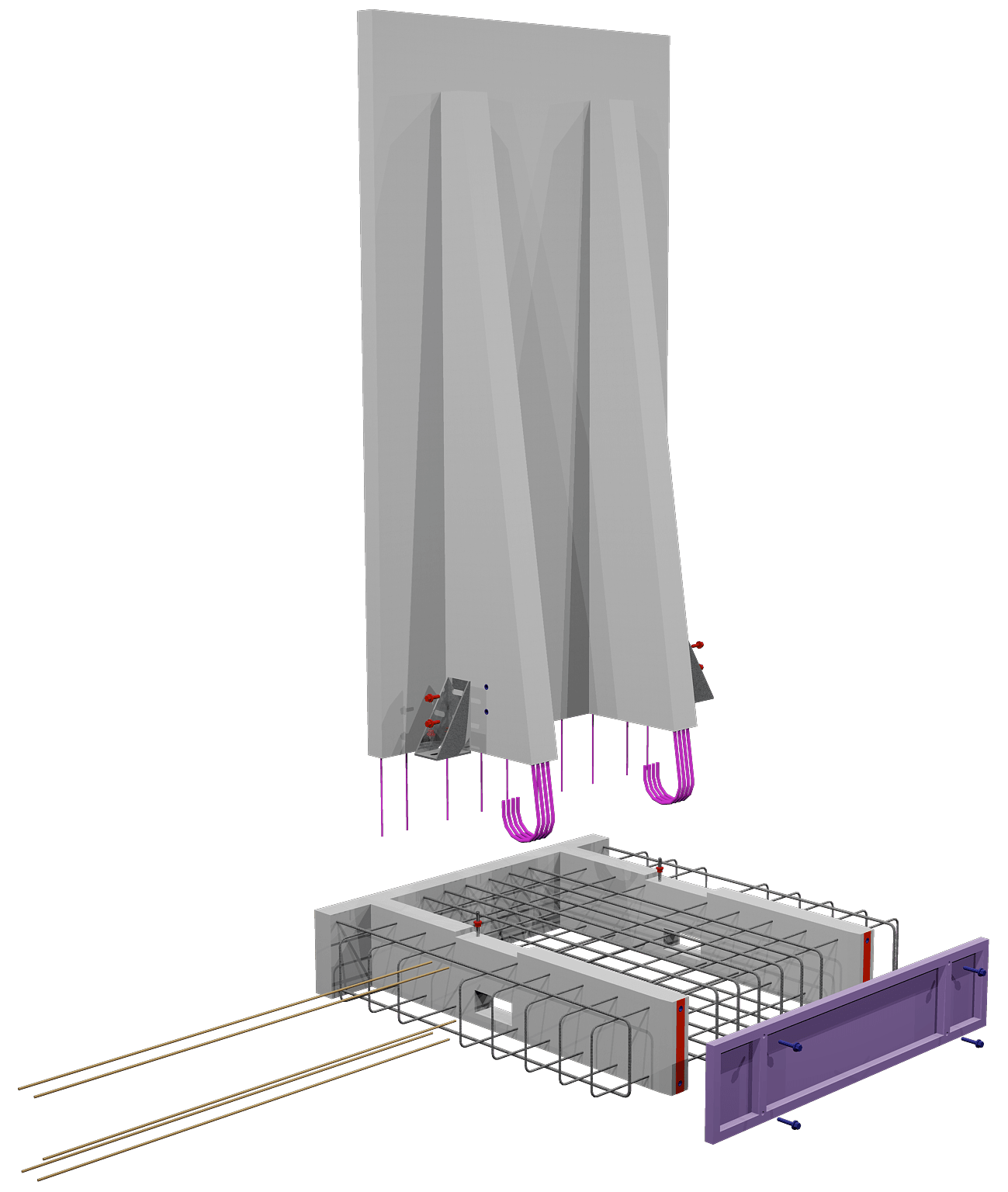

Precast Retaining Wall with Precast STRIP Foundation

They are the most advanced solution, in the construction of Precast Retaining Walls. This technology combines the design advantages of the Precast Wall with the efficiency of the Precast Footing. The two precast elements brings to earth retention systems, ease, precision, speed of installation as well as cost-efficiency.

_

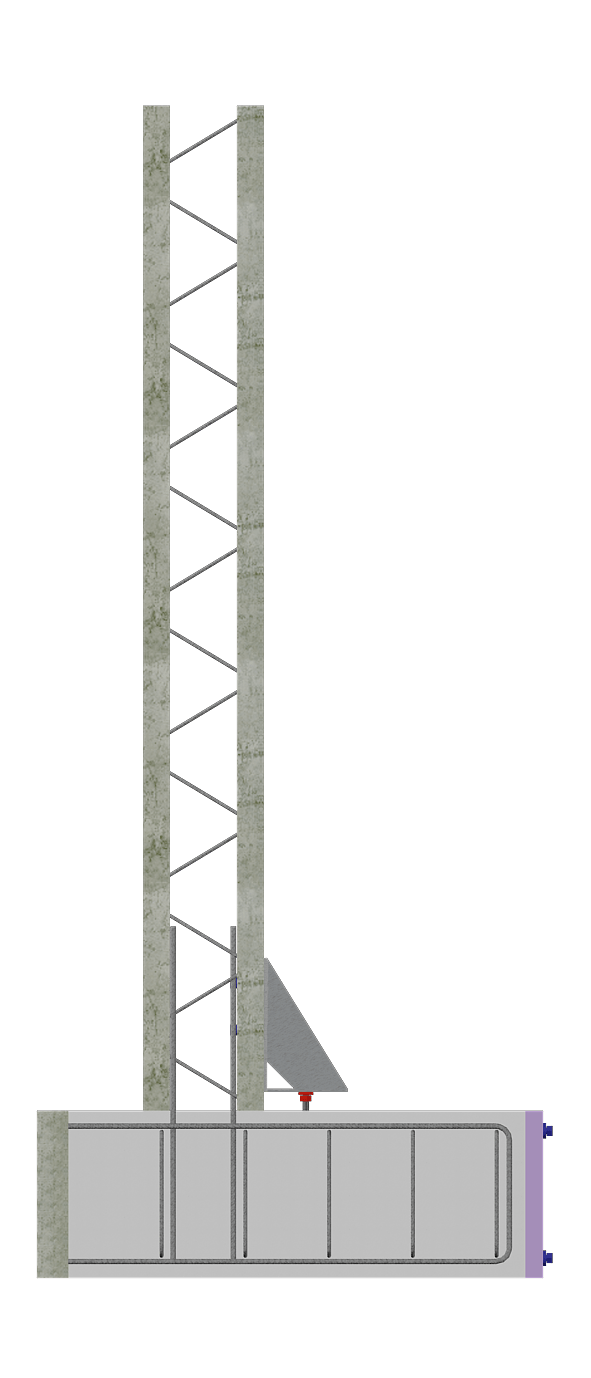

Precast Foundation for Double Wall

Characterised by its reduced weight, Precast STRIP Foundation for Double Wall enables greater savings in installation costs and time while adding monolithic design advantages to the many other construction advantages the MONACHINO Precast whole of structure offer brings. With the many installation advantages, construction time and monolithic designadvantages, Precast STRIP Foundation and Double Wall are a perfect combination.

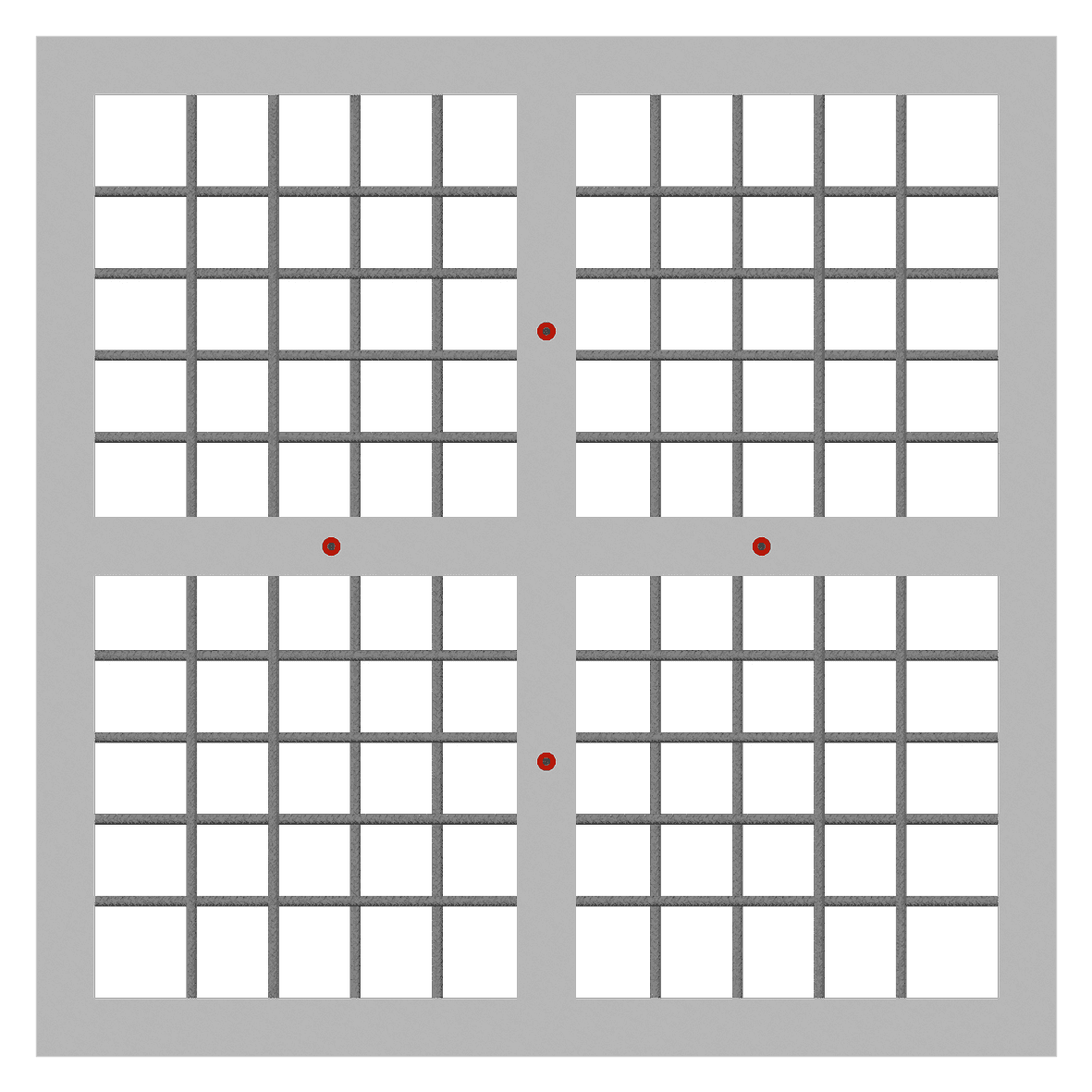

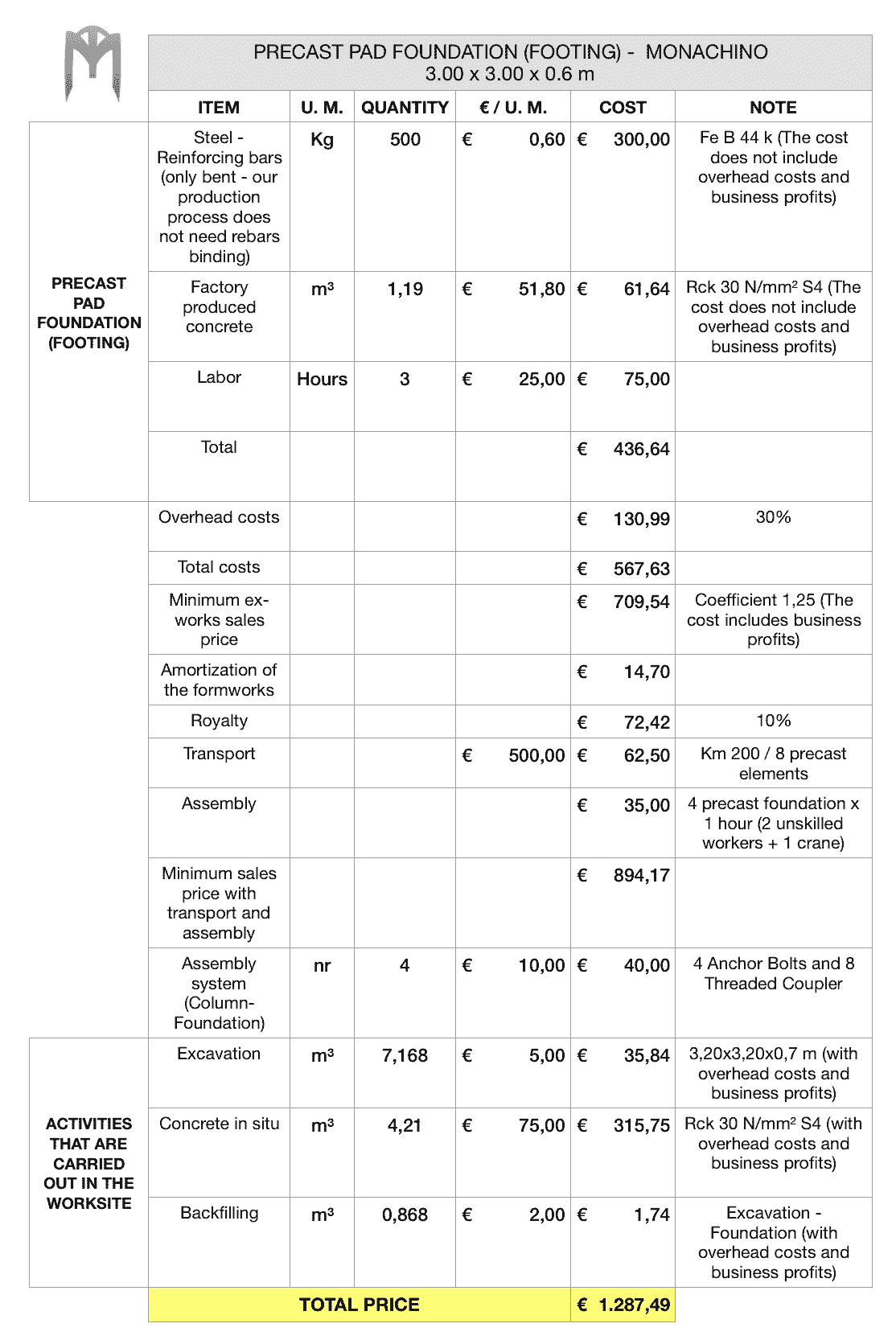

PRECAST PAD FOUNDATION / FOOTING

Opportunity

-

The Italians have been doing concrete since Roman times and this new system of precast concrete foundations is the new state-of-the art in Italy. Now some master licensees are sought for international markets.

This innovative precast footing is about cutting costs, increasing quality and speeding the process of light to very heavy-duty construction. It is a disruptive innovation in a field that is still using methods developed in Roman times.

There is significant amount of knowhow that we can share to smooth the product launch and gain early advocates among project owners.

Current Technology Being Replaced

In the USA and Europe today footings for structures are concrete is poured into lumber or steel forms assembled on-site according to an engineers design. This is known as "cast-in-place".

Steel reinforcement bars (rebar) are often embedded in the concrete in complex patterns and wired for temporary support until the concrete sets.

Rebar often extends out of the footing tobe the connection to a foundation wall or column. Special welded or mechanical connections are needed to connect cast footings with precast walls or columns.

On-site fabrication of rebar for footings is labor intensive and adds days to construction schedules. It is difficult to obtain consistent quality for rebar placement using current field techniques.

Sustainable Competitive Advantage

The precast foundation system offers a sustainable competitive advantage to the precast company that gains the national master license. This is a totally new product category for precast companies, gaining them below-ground work that they do not currently profit from.

Contractors using the system will have fewer weather delays, saving overtime and completion deadline penalties. Contractors using the system will win more bids and grow their business. Ownerswill stretch construction budgets and get higherquality and earlier completion dates.

-

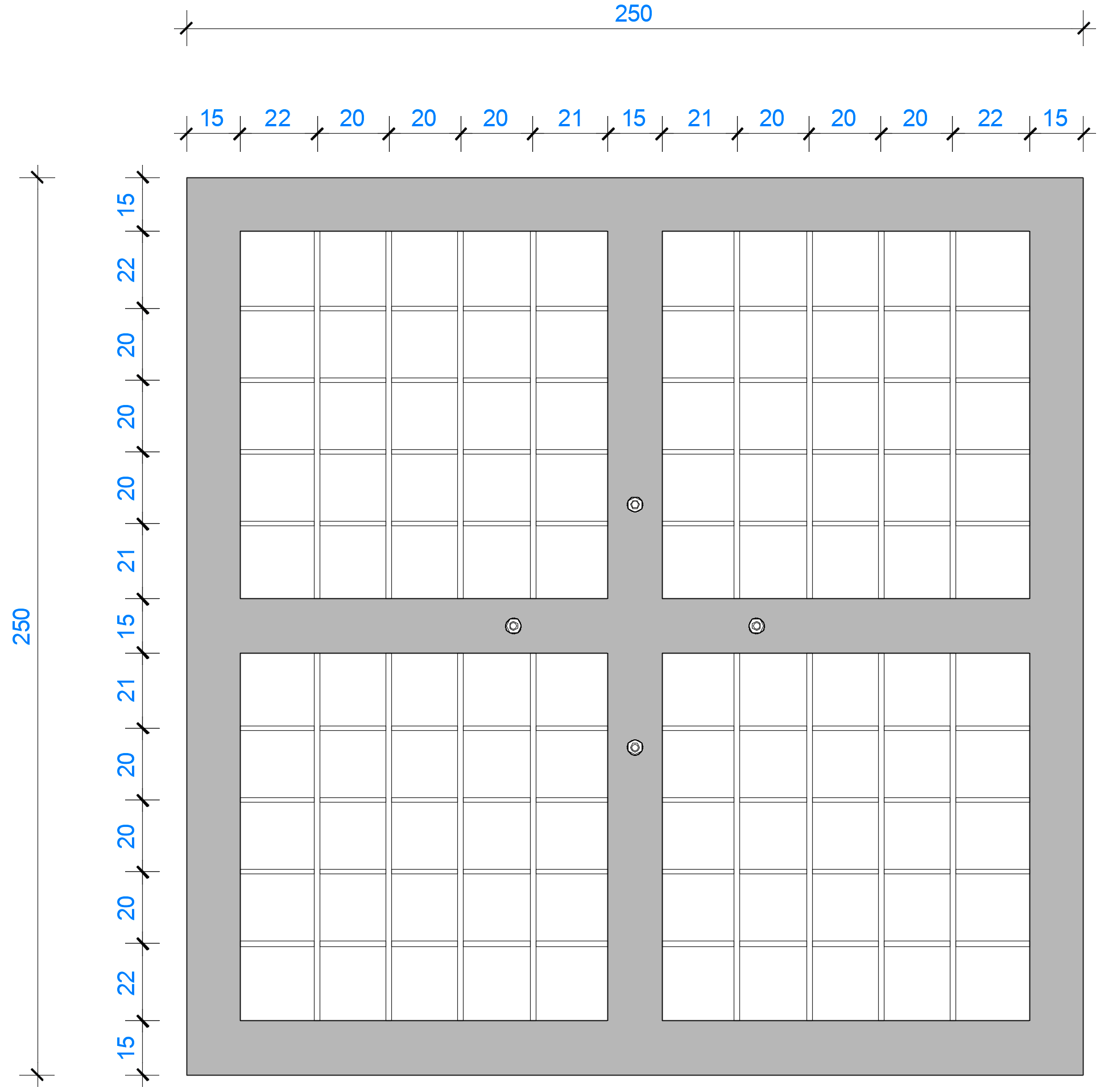

The precast foundation is a reinforced concrete element made up of a tied rebar beam cage incorporated within a semi-precast concrete element which acts as formwork. The element can be used in the construction of column and wall foundation of any type and is suitable for any elevated structure.

The use of the precast foundation eliminates all those inconveniences that crop up during the construction of foundations using traditional methods (for example, cast-in-place), aiming to halve the costs involved in constructing a foundation structure, greater jobsite safety for workers and a turnaroundspeed without precedence.

_

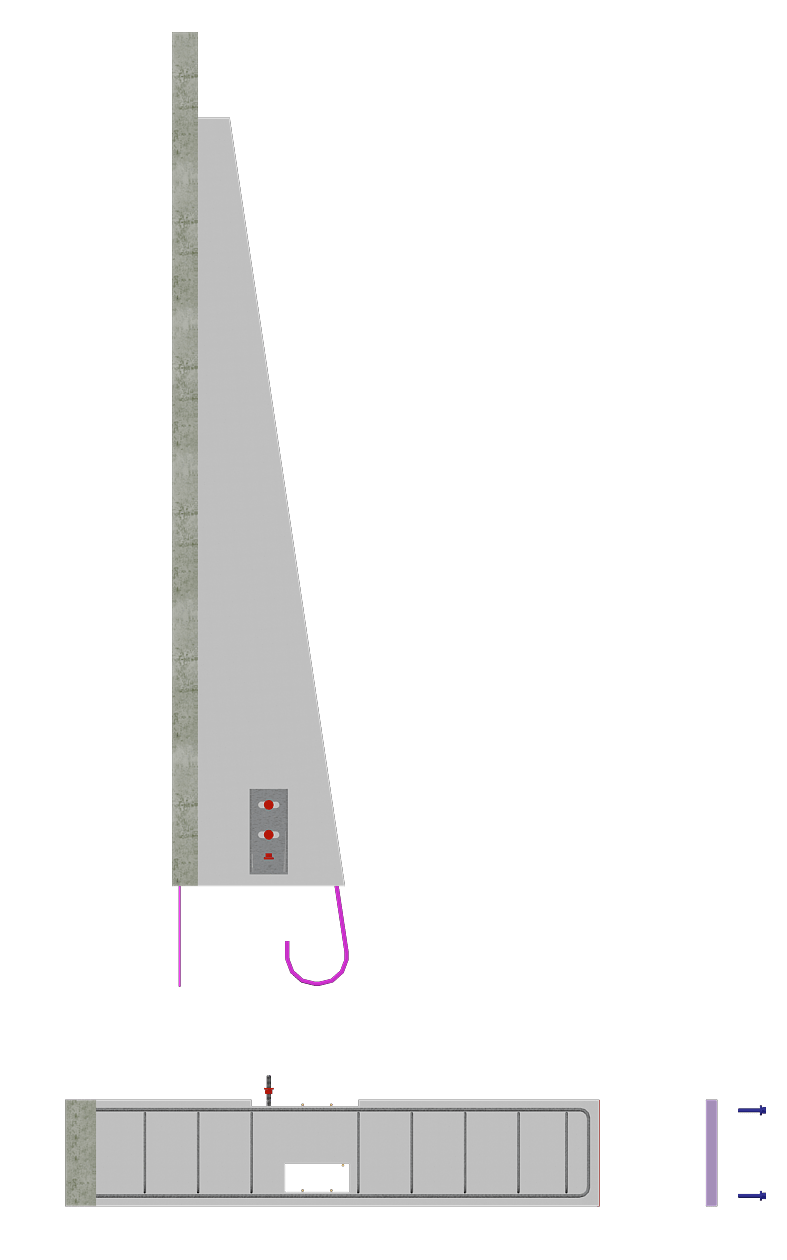

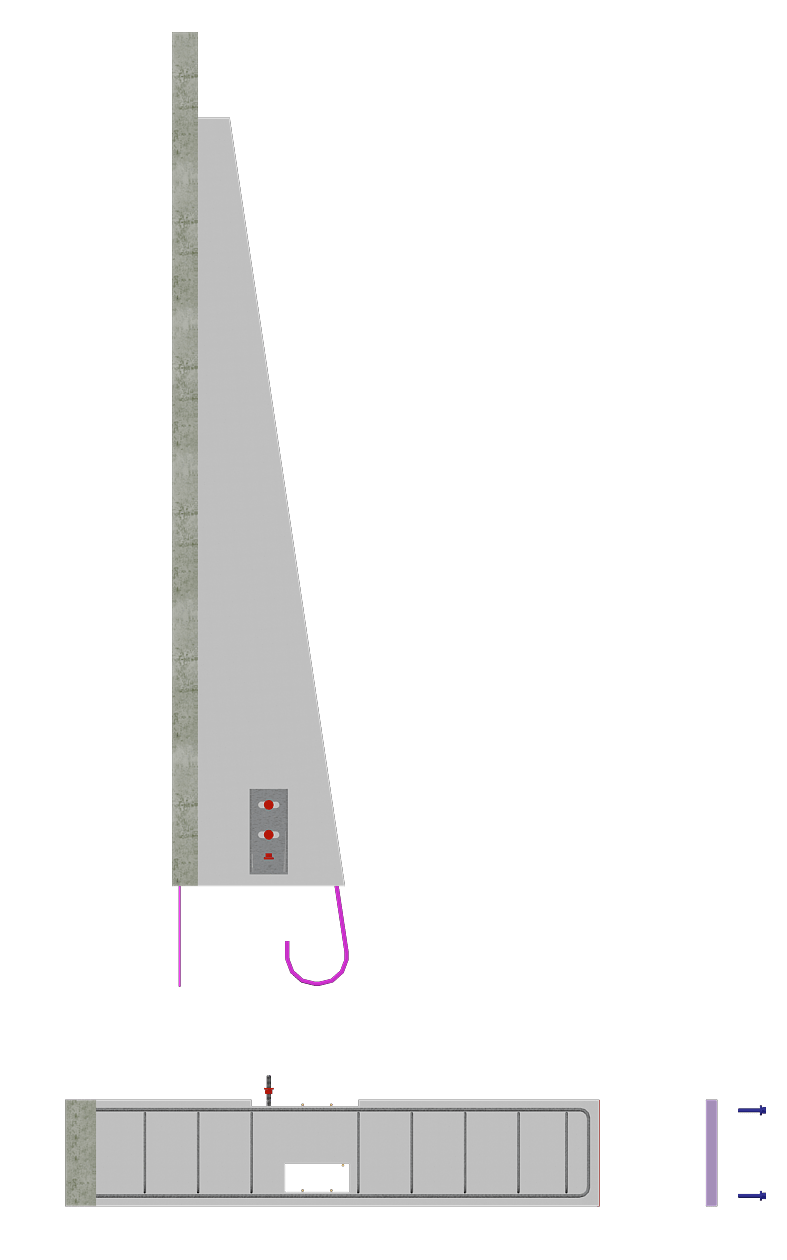

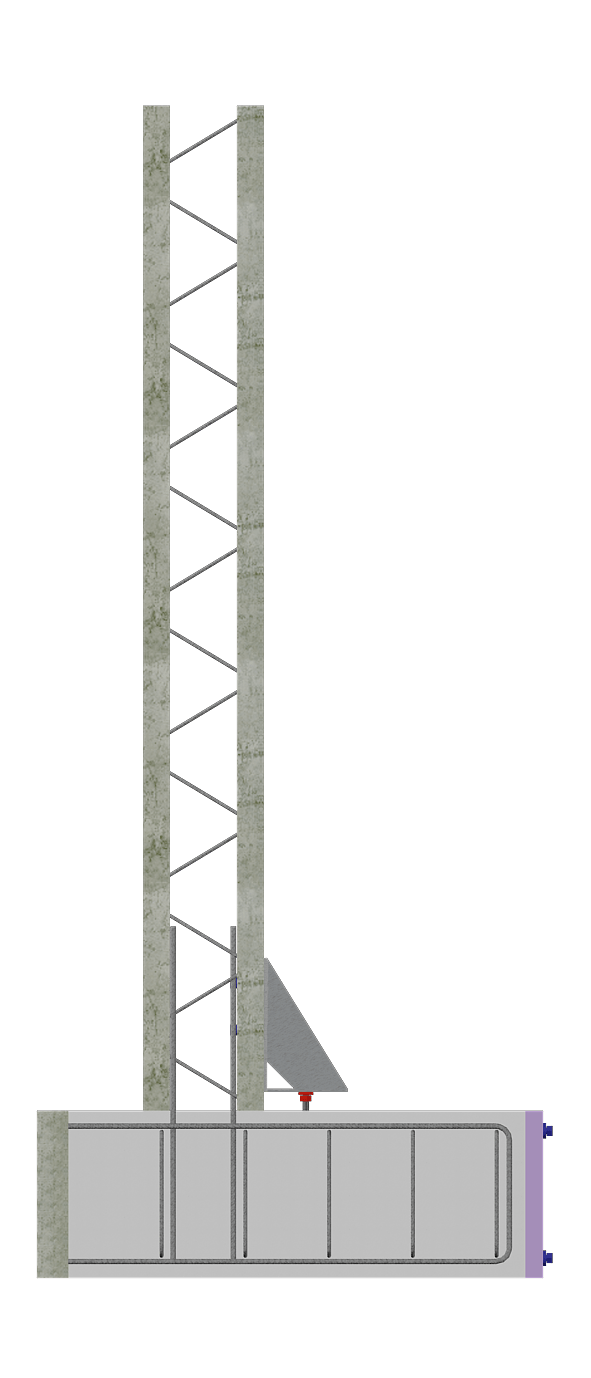

PRECAST RETAINING WALLS

WITH PRECAST STRIP FOOTINGS / FOUNDATIONS

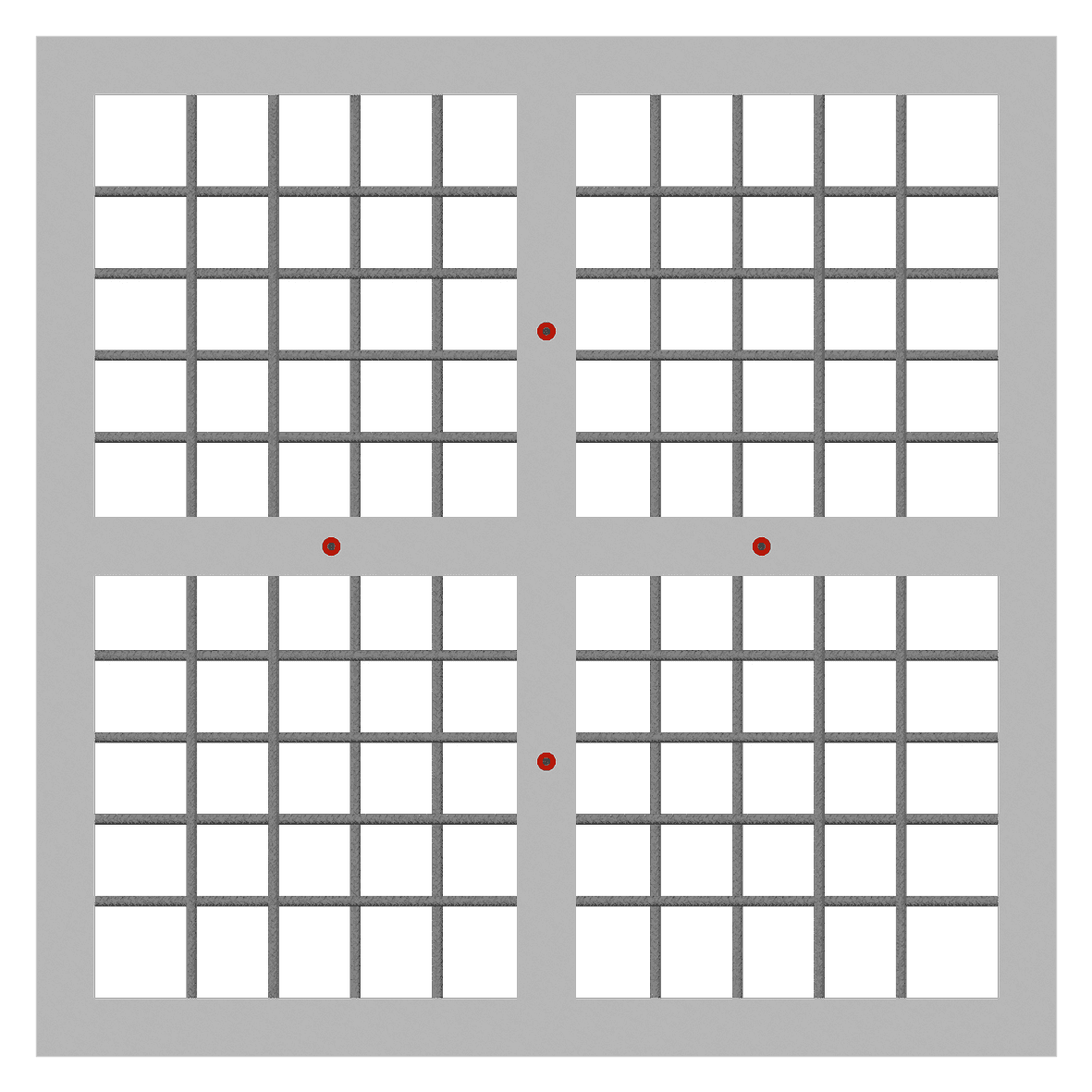

Precast retaining walls are vibrated concrete structures for retaining soil. They are made up of a line of full-height modular panels. The side facing the soil is endowed with one or more vertical stiffening ribs that go from the base to the top of the wall.

They are placed on a precast footing of varying size that has been laid beforehand. The two elements are then anchored through a concrete pour.

The precast foundation can be both direct (shallow) and indirect (deep). If the soil requires it, piles or micropiles can be driven into the ground before the laying of the precast foundation. Both the precast elements and their highly automatized production techniques are protected by industrial patents and are perfectly suitable for any kind of soil pressure, be it low, medium or high.The wall facing can be made perpendicular to the laid substructure or inclined between 0% and 15%. Placement is very quick and produces a structure which is ready to be filled. The precast retaining walls are produced in four different types: exposed cement facing, covered in local stone or with horizontal flowerbeds (stone-grass or cement-grass). They can be used for the construction of retaining walls for embankments, toe walls, counterscarp walls, bridge abutments, abutments for artificial tunnels and noise barriers.

Learn more →

We have been a leader in the drafting of patents in the field of new precast elements in reinforced concrete for over fifteen years. These are characterized by their marked originality, the result of the continuous research carried out by our technical staff.

What makes our name synonymous of reliability and trustworthiness is the essentiality of the values on which we base our productive experience, above all, the ability to find solutions for the customer’s every need, thanks to the expert and well-qualified support of technicians, architects and engineers who work every day in the field of research and innovation to offer solutions that are increasingly advanced and creative.

Learn more →