PRECAST RETAINING WALLS

ON PRECAST STRIP FOUNDATIONS / FOOTINGS

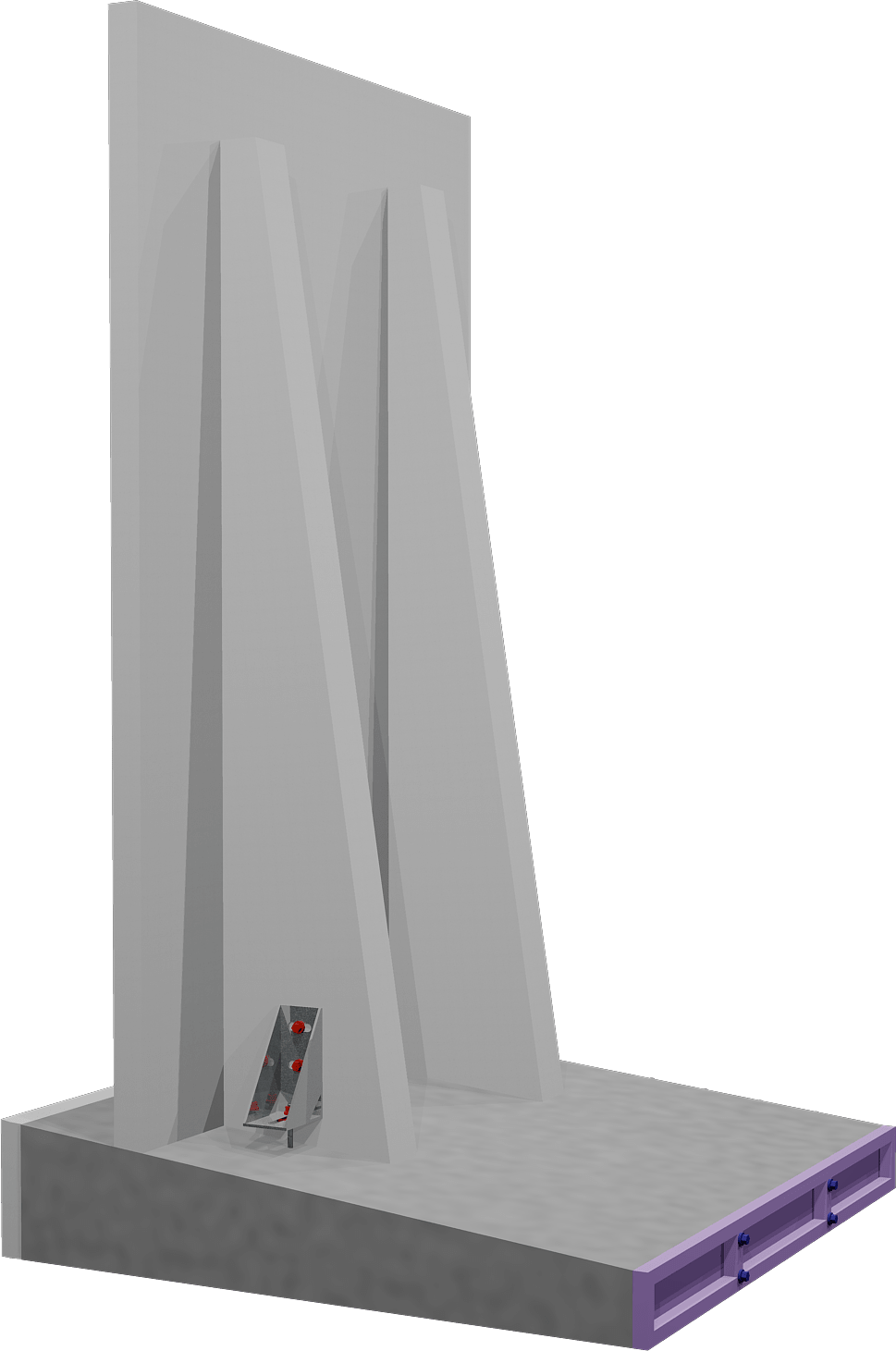

Precast Retaining Walls are vibrated concrete structures for retaining soil. They are made up of a line of full-height modular panels. The side facing the soil is endowed with one or more vertical stiffening ribs that go from the base to the top of the wall.

They can be placed on a Precast Foundation of varying size that has been laidbeforehand. The two elements are then anchored through a concrete pour.

The Precast Foundation can be both direct (shallow) and indirect (deep). If the terrain requires it, piles or micropiles can be driven into the ground before the laying of the Precast Foundation.

The Precast Retaining Walls are produced in four different types: exposed cement facing, covered in local stone or with horizontal flowerbeds (stone-grass or cement-grass). They can be used for the construction of retaining walls for embankments, toe walls, counterscarp walls, bridge abutments, abutments for artificial tunnels and sound-absorbing barriers.

Both the precast elements and their highly automatized production techniques are protected by industrial patents and are perfectly suitable for any kind ofsoil pressure, be it low, medium or high. The wall facing can be made perpendicular to the laid substructure or inclined between 0% - 15%. Placement is very quick and produces a structure which is ready to be filled.

Fair-faced concrete Wall

Wall covered with local stone

Stone-Grass Wall

ITEM SPECIFICATIONS

Precast Concrete Retaining Wall with cement facing, covered in stone with horizontal flowerbeds, factory produced certified or controlled series products supplied with a suitable Precast Foundation, made up of vertical or sloping panels in vibrated cement with stiffening ribs on the side facing the soil which go from bottom to top, from which rebars jut out to enable fastening with the Precast Foundation; the visible part can be covered with a natural or artificial stone facing which blends in with the surrounding ecosystem to safeguard the environmental impact.

The wall can be fitted with horizontal self-draining flowerbeds so that vegetation may easily grow to allow the wall to blend in better with the surrounding environment.

The wall is sized according to the current regulations regarding the verification of sliding, toppling and the maximum load of the foundation-wall-soil structure and according to current regulations regarding works carried out in reinforced concrete and, where necessary, according to current antiseismic regulations.

PRECAST STRIP FOUNDATION FOR RETAINING WALLS

The Precast Foundation is a reinforced concrete element made up of a tied rebar beam cage incorporated within a semi-precast concrete element which acts as formwork.

The geometric dimensions and the steel area are established through static calculations elaborated according to the distributed of loads N, Mx, Tx, My, Ty and the pt pressure admissible on the terrain.

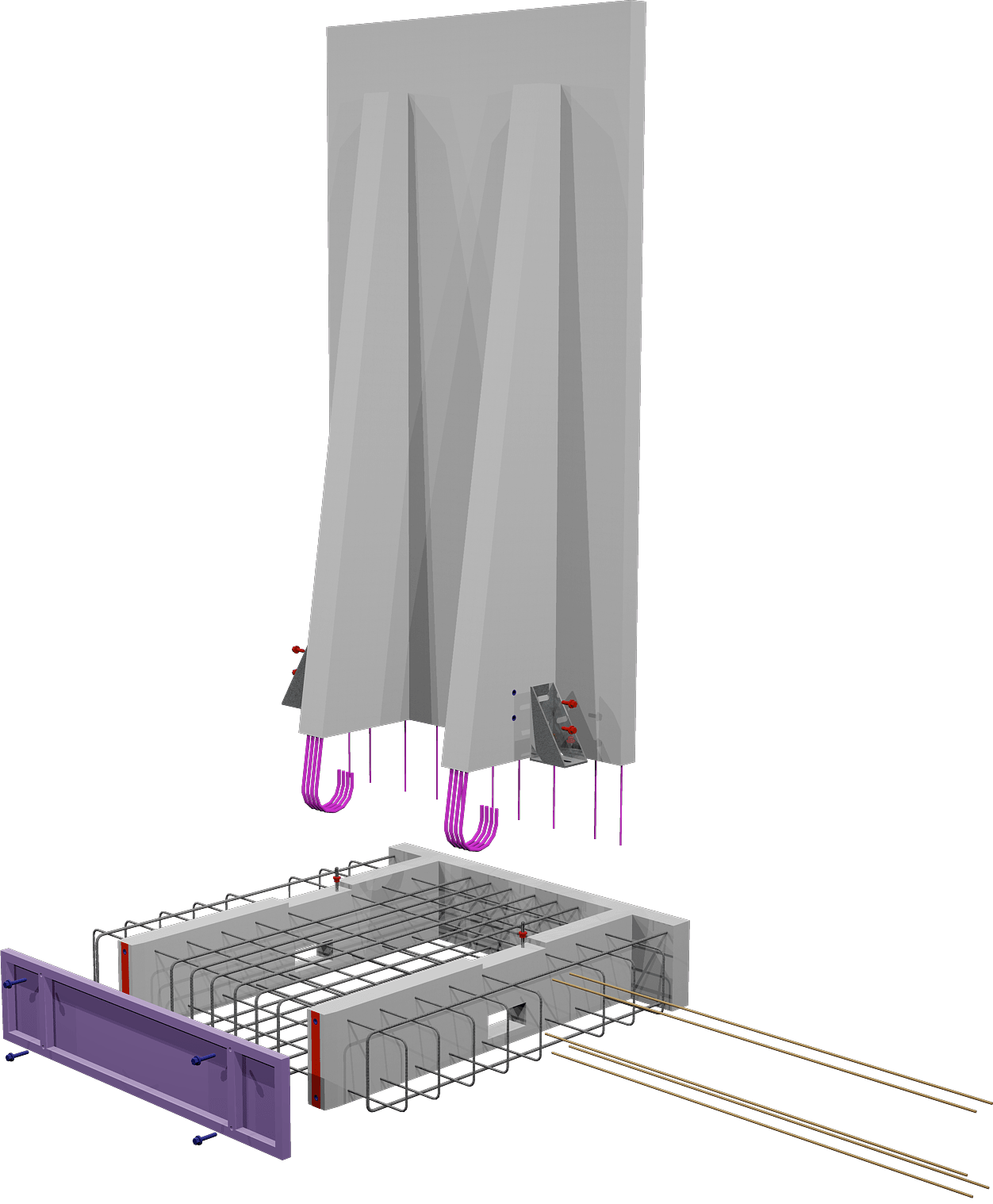

ASSEMBLY RETAINING WALL AND FOUNDATION

During the assembly process, the Precast Foundation is placed on the lean concrete, which has previously been prepared (1), then the Retaining Wall is mounted on the foundation and the bent rebars jutting out from the base (2) are inserted inside the Foundation element (3). A final casting of concrete embeds the Wall’s rebars inside the Precast Foundation (4). The work is completed with the removal of all adjustment devices (5).

For the assembly and alignment of the Retaining Wall, adjusting devices are used. These allow an easy, fast and precise installation.

During the production phase of the Precast Strip Foundation, two anchor bolts are left within its internal concrete beams, while the Retaining Wall is equipped with four threaded couplers. The adjusting devices are fixed tothe anchor bolts using nuts and to the Retaining Wall using bolts.

This system not only allows the Precast Retaining Wall to be aligned with pinpoint precision, but also eliminates any kind of shoring during the assembly.

The two adjusting devices will be dimensioned in relation to the weight and other strains to which the Retaining Wall is subject and are used merely for assembling the precast elements.

CONCRETING

When the concrete inside of the Precast Foundation has cured, all the adjusting devices are removed.

Thanks to the technology with which it has been designed, the two precast structures manage to form, after the final pour of concrete, a perfect monolithic structure.

In order to optimise the amount of the concrete using for the construction of the Wall the Precast Foundation can be produced slightly sloped.

DEEP FOUNDATION ON PILES OR MINI PILES

The precast element may be mounted both in a shallow foundation and a deep one. When faced with conditions in which the admissible pt pressure cannot bear the N, Mx, Tx, My, Ty loads, piles or mini piles are introduced into the foundation.

The jutting out reinforcements at thehead of the pile are incorporated within the footing base through the pouring of concrete.

DIMENSIONS

The Precast Foundation can be produced in different forms and dimensions to satisfy every design and structural need.

THE ADVANTAGES OF THE PRECAST STRIP FOUNDATION

- 40% savings on completion times.

- 30% savings on total work costs.

- The work is terminated without the need of skilled labor for the positioning of the foundation reinforcement.

- Speed of assembly and adjustment of the Precast Retaining Walls.

- Pinpoint precision in the adjustment of the elements.

- Braces are not needed.

Our system turns out to be the cheapest and the most efficient technology for the construction of PRECAST RETAINING WALLS on the international market.

ABOUT US

We have been a leader in the drafting of patents in the field of new precast elements in reinforced concrete for over fifteen years. These are characterized by their marked originality, the result of the continuous research carried out by our technical staff.

What makes our name synonymous of reliability and trustworthiness is the essentiality of the values on which we base our productive experience, above all, the ability to find solutions for the customer’s every need, thanks to the expert and well-qualified support of technicians, architects and engineers who work every day in the field of research and innovation to offer solutions that are increasingly advanced and creative.

Copyright © 2008 - 2023 Monachino Technology

All rights reserved