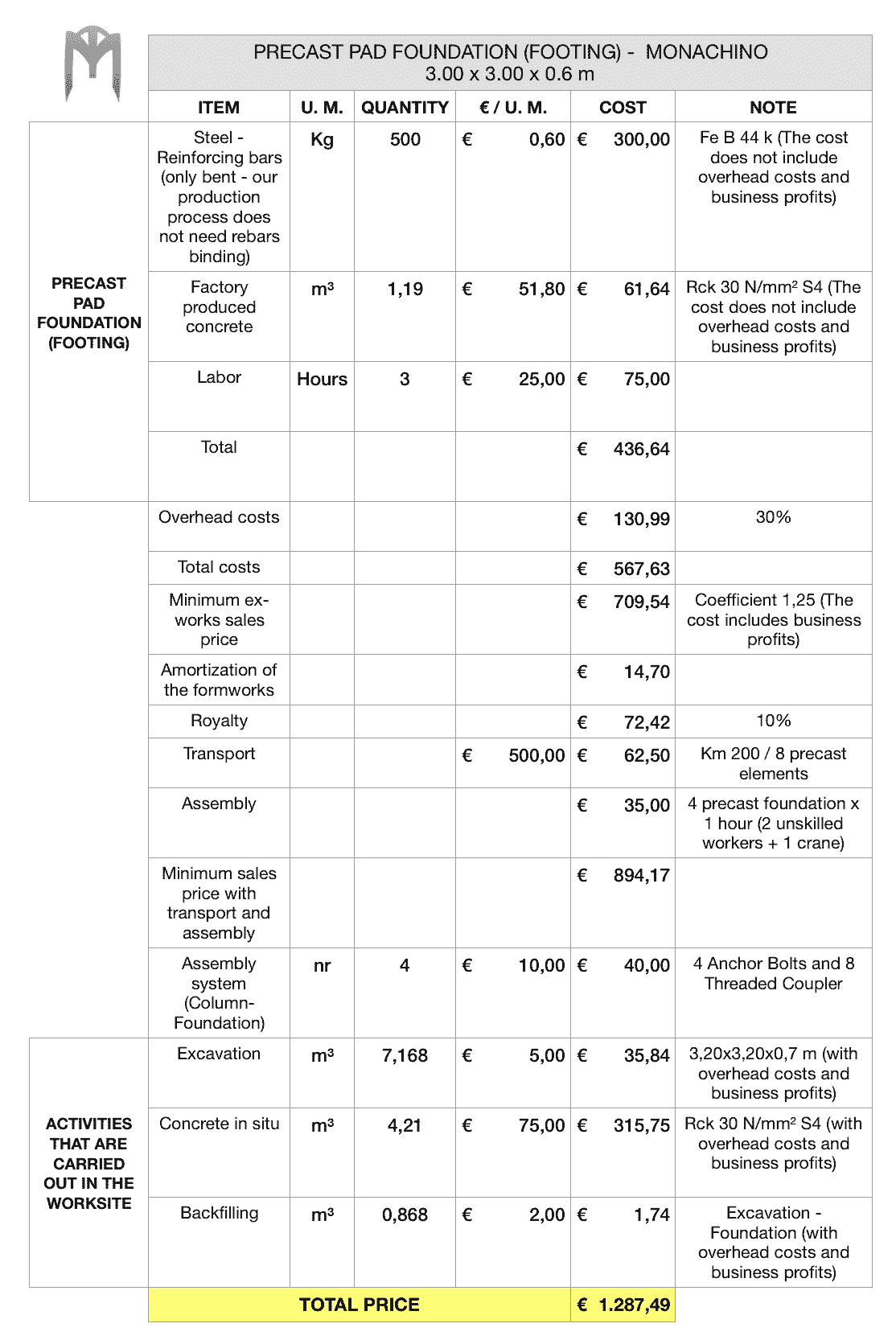

PRECAST PAD FOUNDATION (FOOTING)

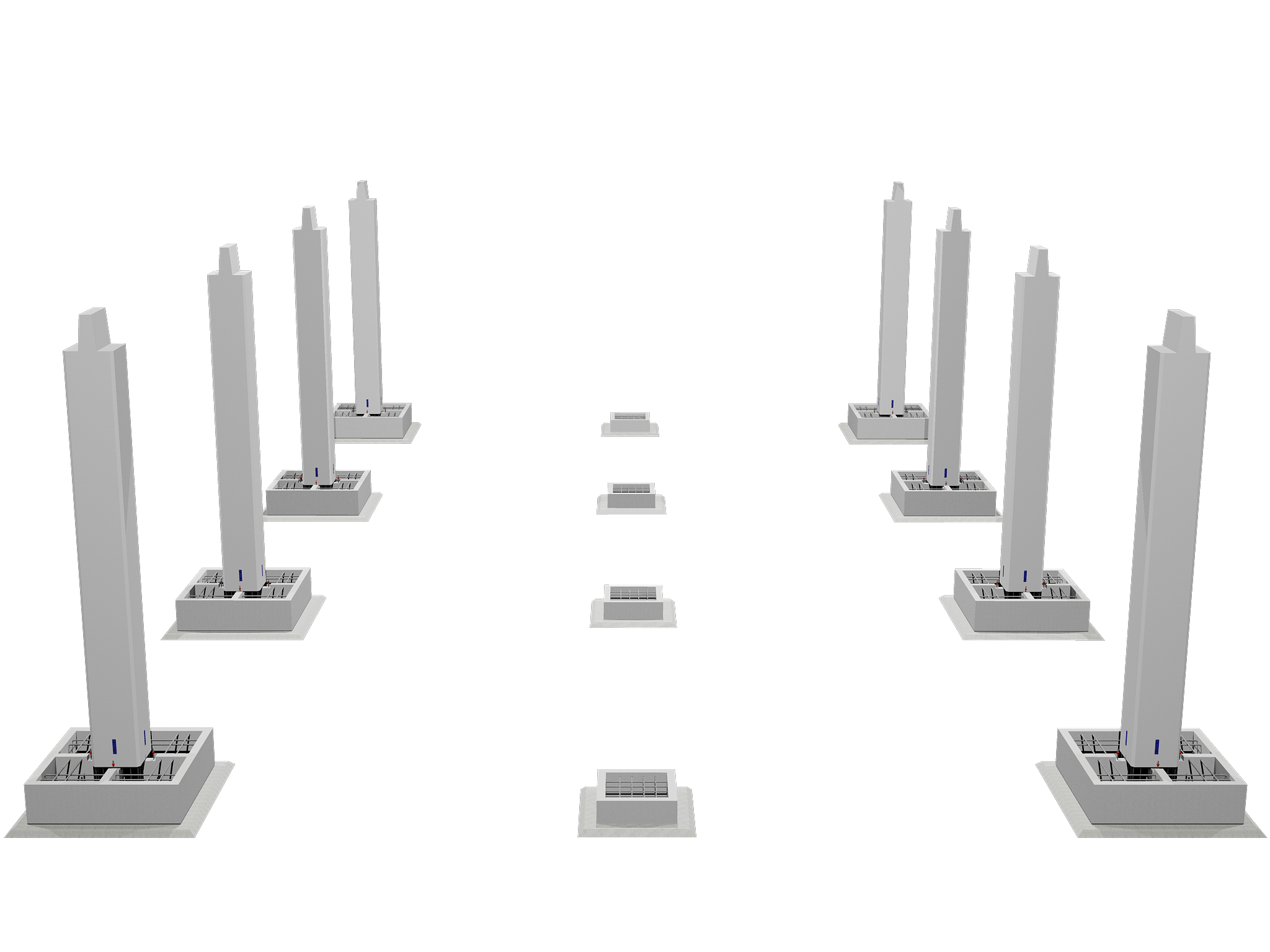

PRECAST PAD FOR SHALLOW FOUNDATION

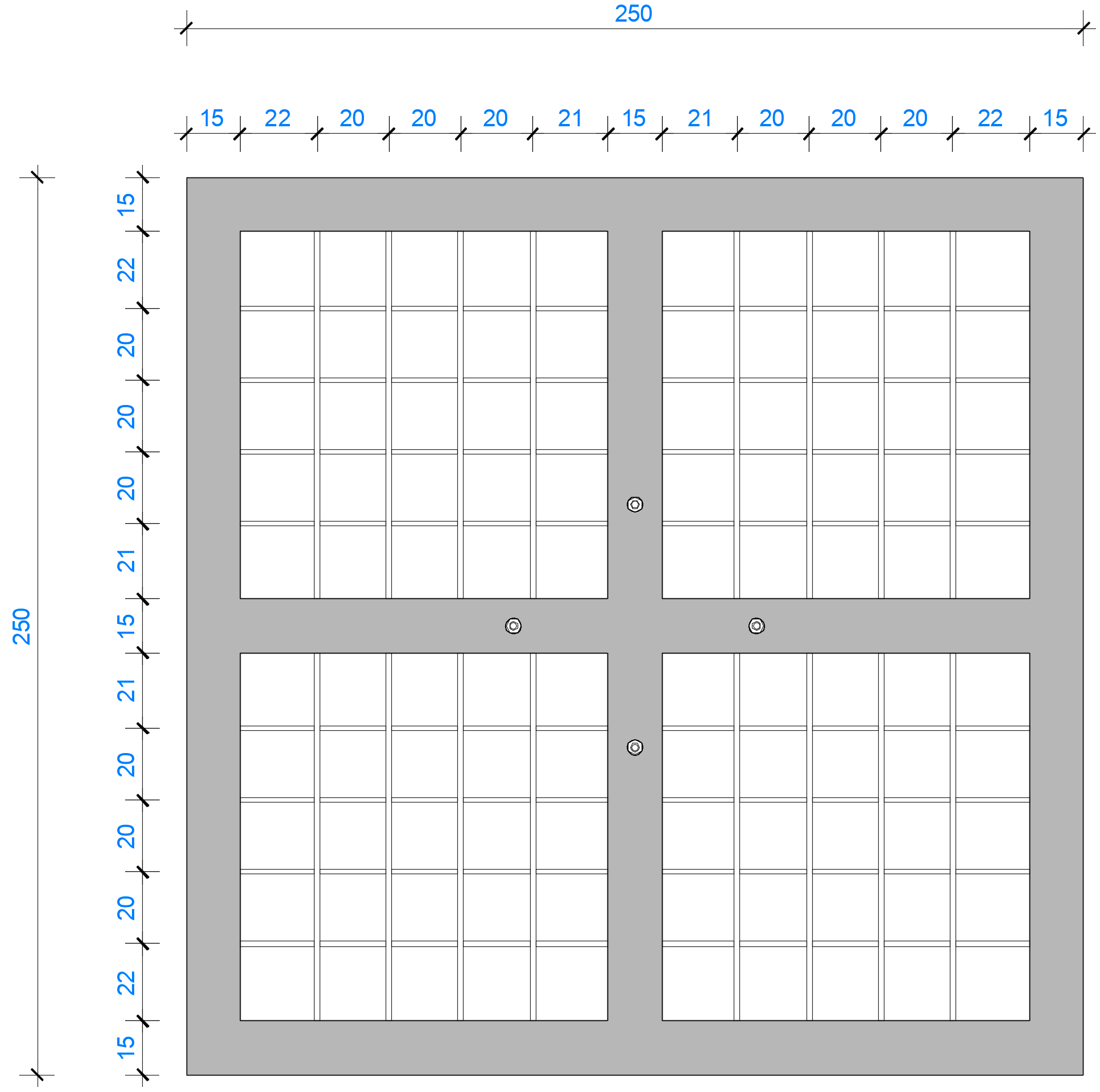

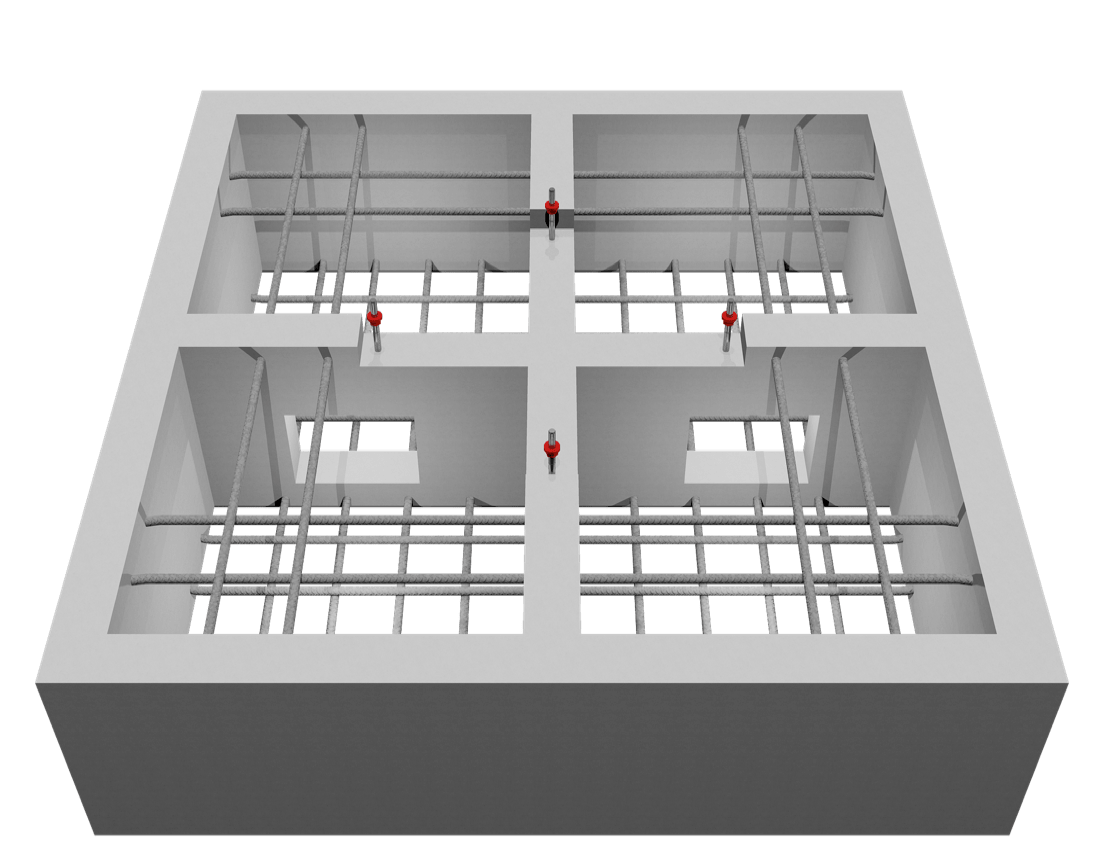

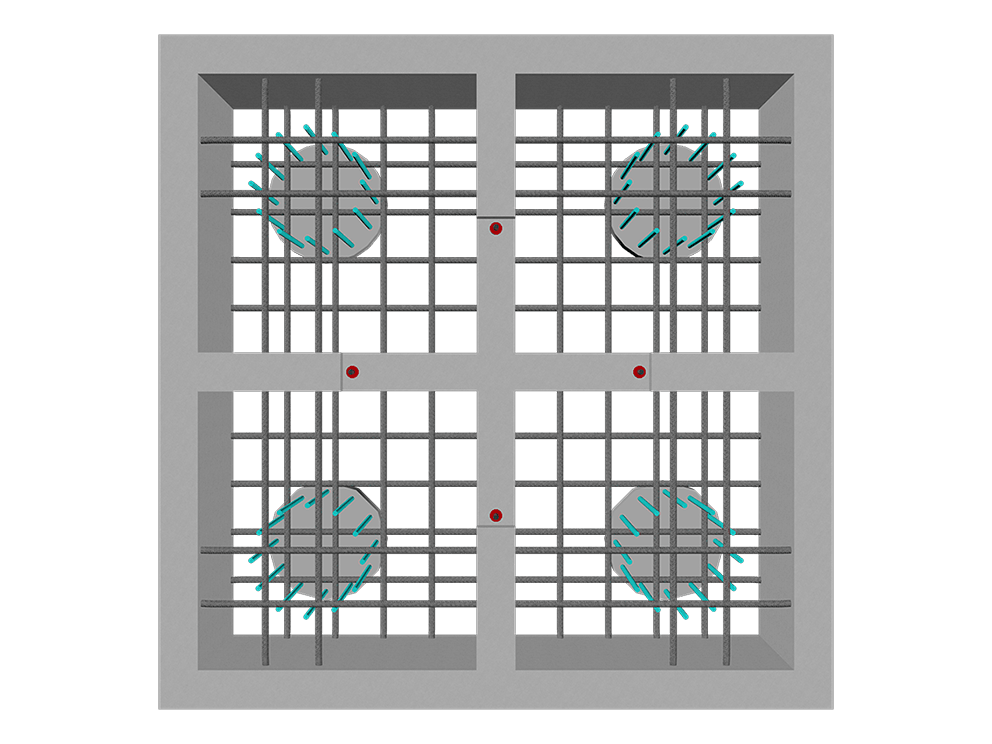

The Precast Foundation is a reinforced concrete element made up of a tied rebar beam cage incorporated within a semi-precast concrete element which acts as formwork. The geometric dimensions and the steel area are established through static calculations elaborated according to the distributed of loads N, Mx, Tx, My, Ty and the pt pressure admissible on the terrain.

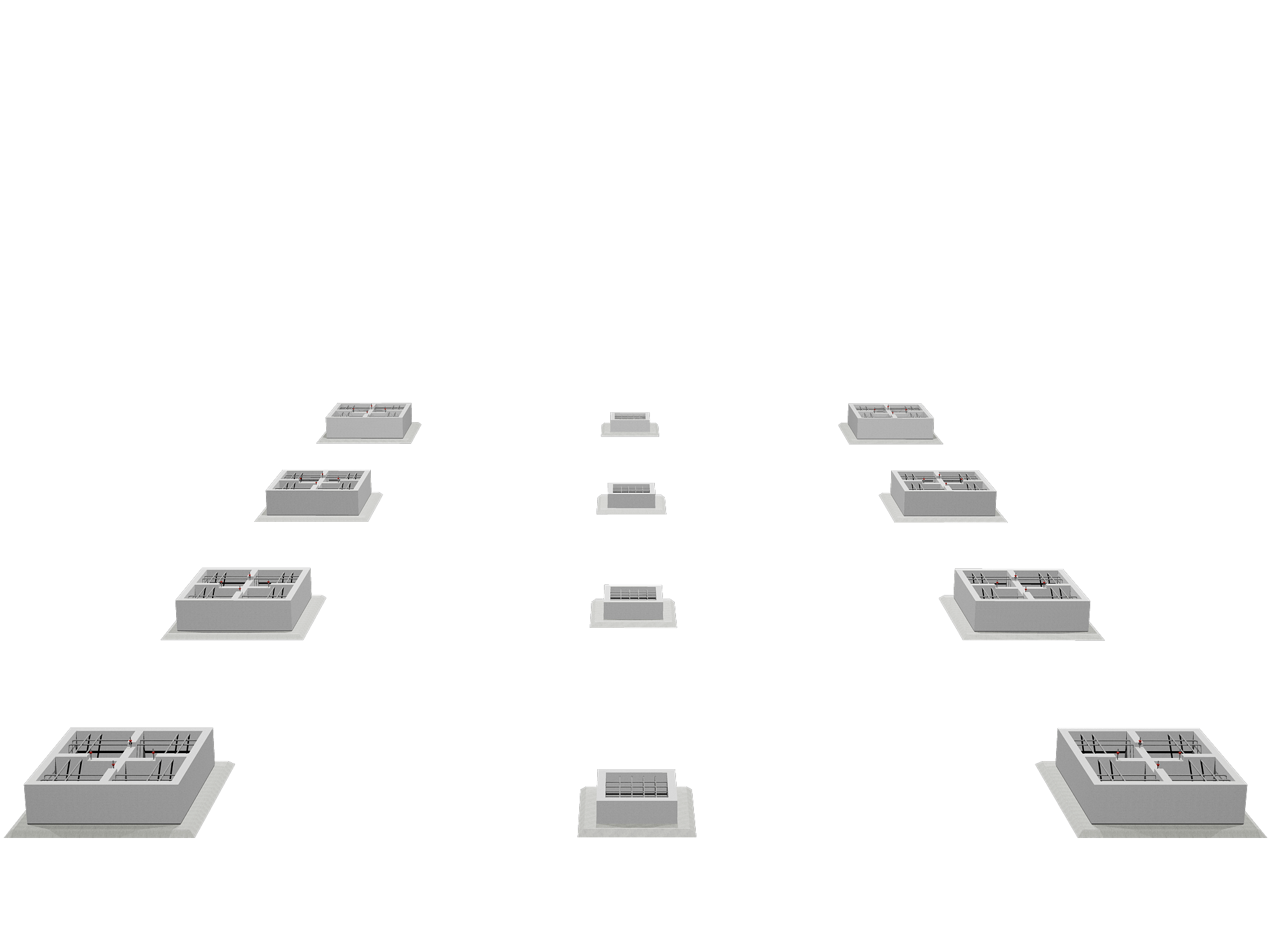

The Precast Foundation can be produced in different forms and dimensions to satisfy every design and structural need.

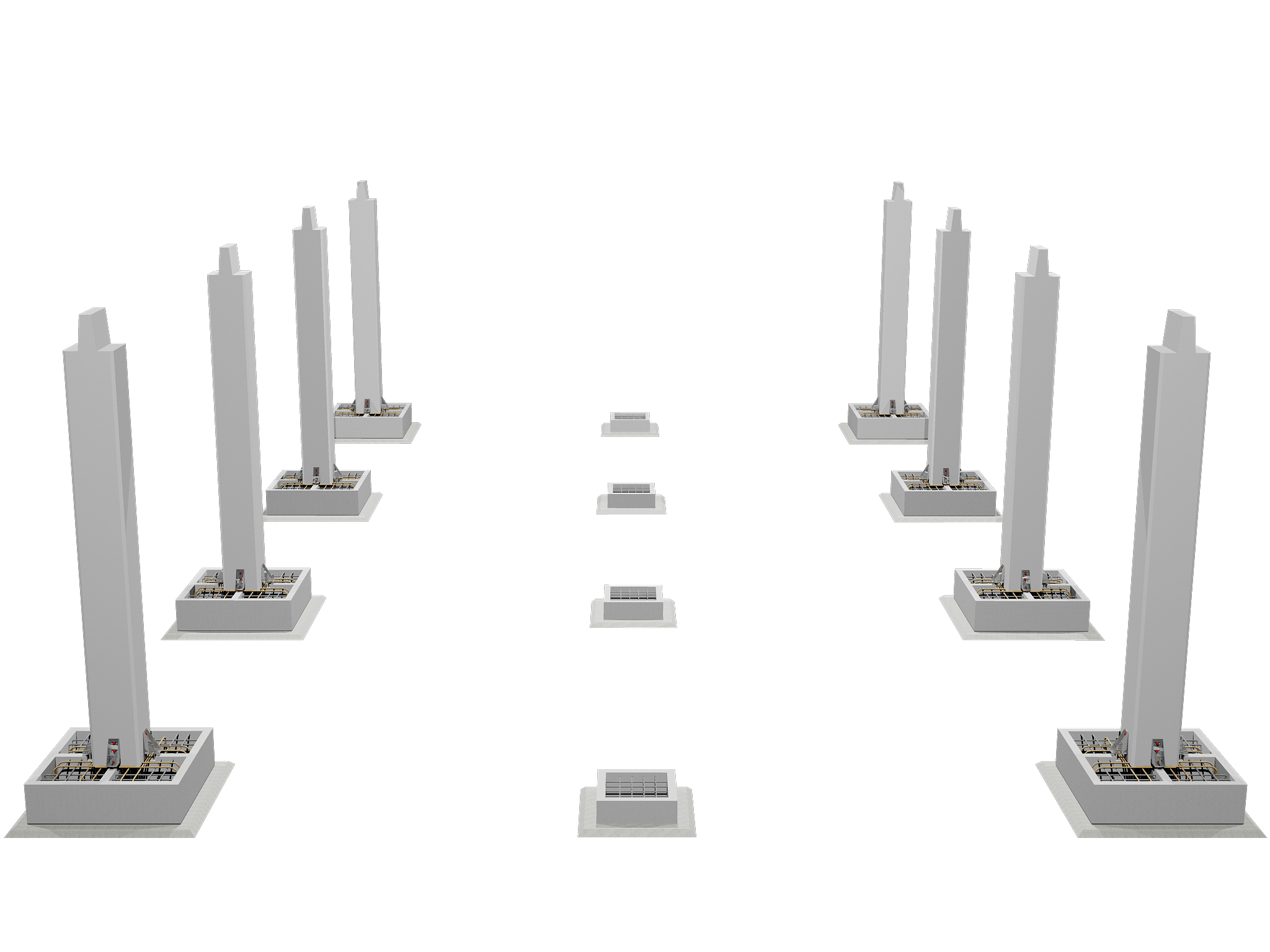

PRECAST PAD FOR DEEP FOUNDATIONS ON PILES OR MINI PILES

The image illustrates that the precast element may be mounted both in a shallow foundation and a deep one. When faced with conditions in which the admissible pt pressure cannot bear the N, Mx, Tx, My, Ty loads, piles or mini piles are introduced into the foundation.

The jutting out reinforcements at the head of the pile are incorporated within the footing base through the pouring of concrete.

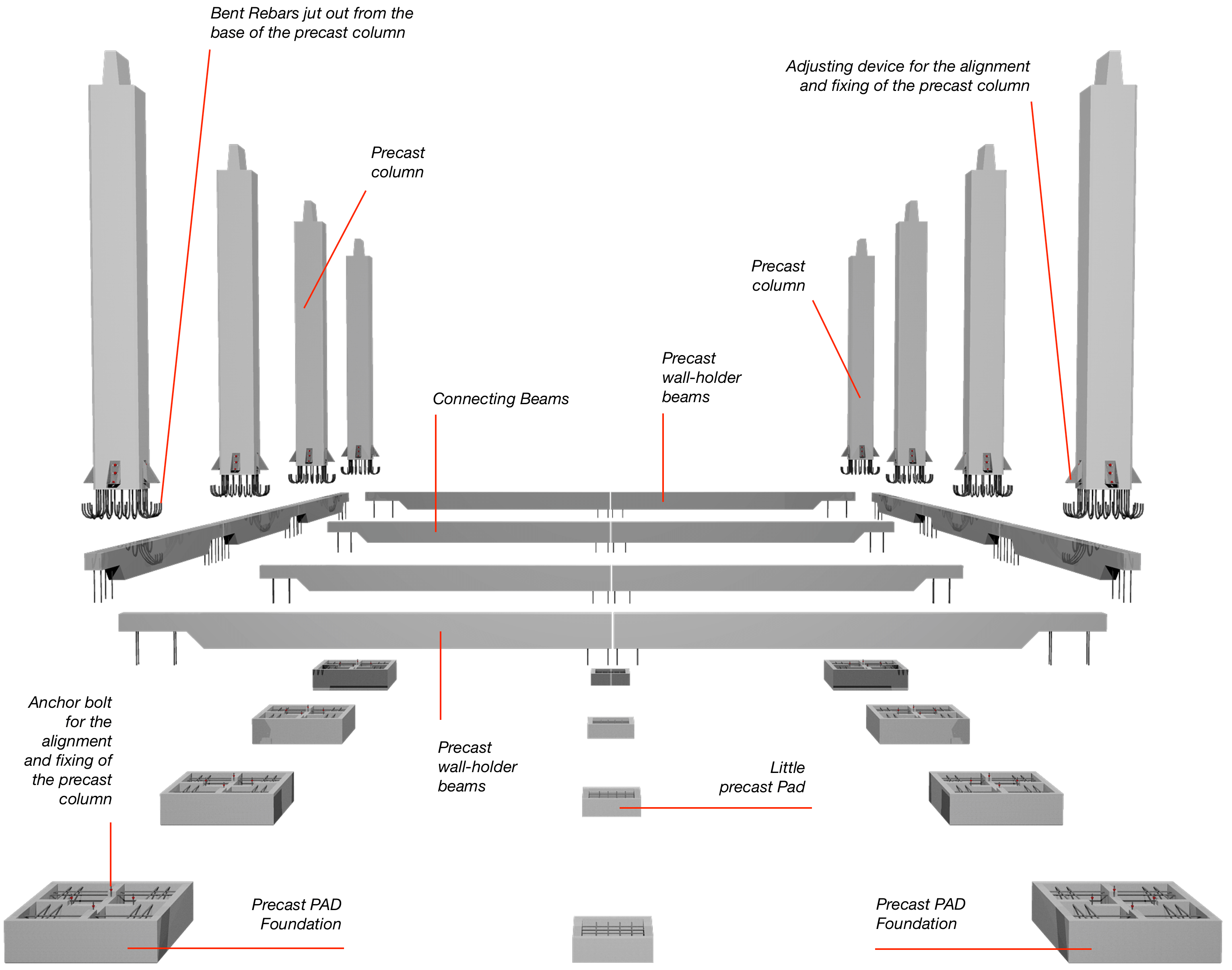

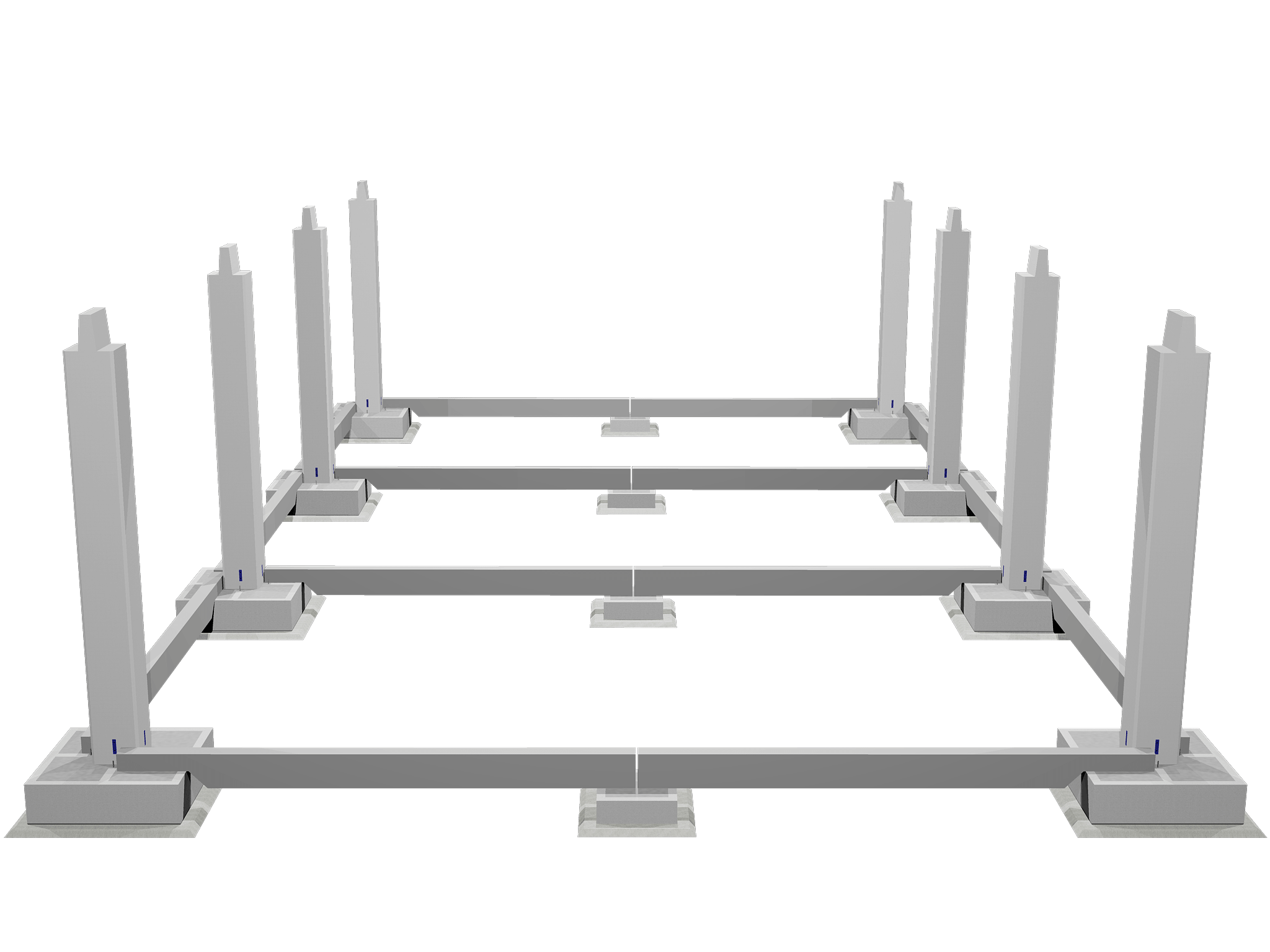

ASSEMBLY

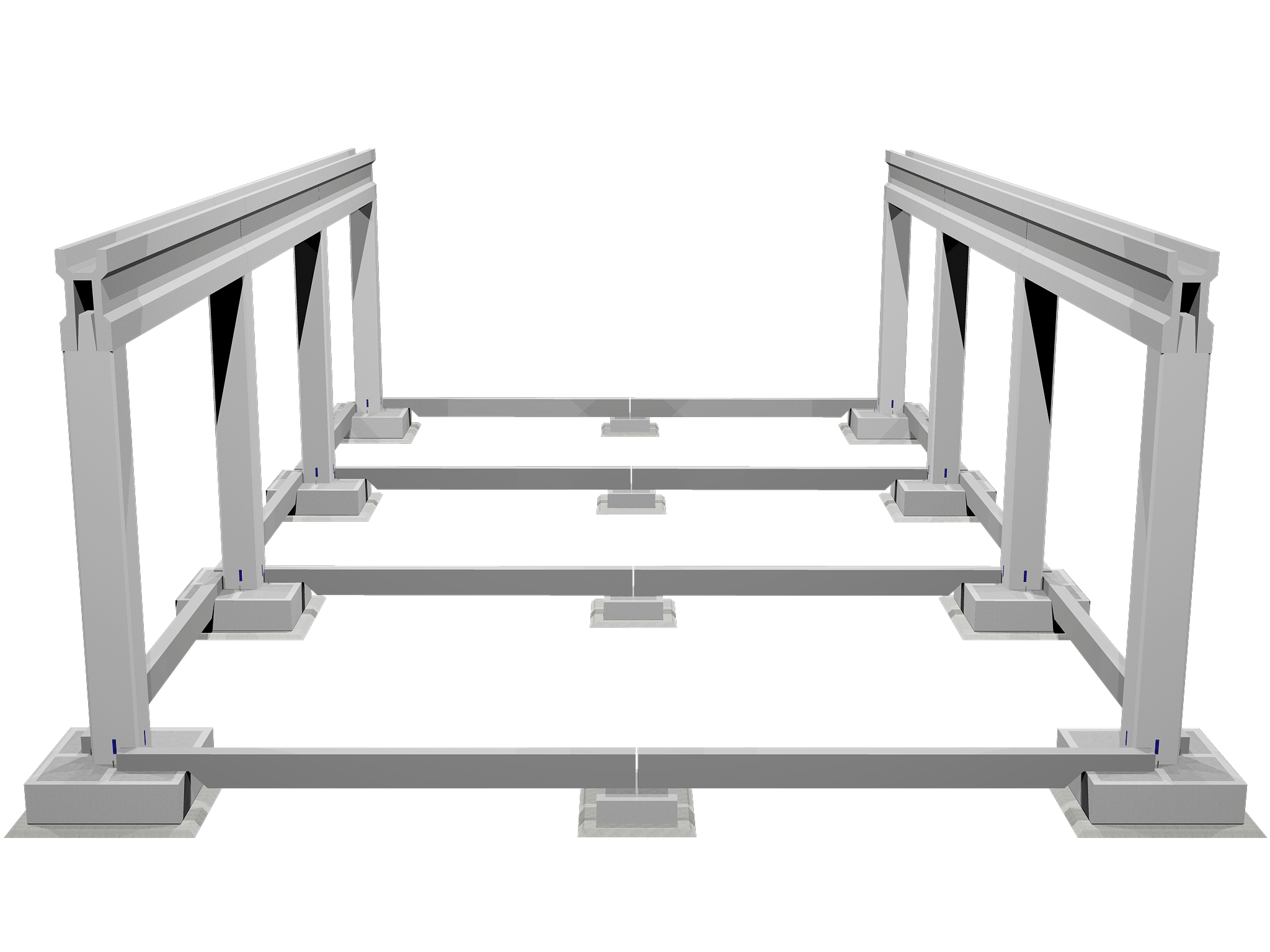

During the assembly process, the Precast Pad Foundation is placed on the lean concrete, which has previously been prepared (1), then the precast column is mounted on the pad foundation and the bent rebars jutting out from the base (2) are inserted inside the Foundation element (3). A final casting of concrete embeds the column’s rebars inside the Precast Foundation (4). The work is completed with the removal of all adjustmentdevices (5).

For the assembly and alignment of the precast column, adjusting devices are used. These allow an easy, fast and precise installation.

During the production phase of the Precast Foundation, four anchor bolts are left within the central concrete walls, while the precast column is equipped with eight threaded coupler. The adjusting devices are fixed to the anchor bolts using nuts and to the precast column using bolts.

This system not only allows the precast column to be aligned with pinpoint precision, but also eliminates any kind of shoring during assembly.

The four connections will be dimensioned in relation to the weight and other strains to which the column is subject and are used merely for assembling the elements. When the concrete inside of the Precast Foundation has cured, all the adjusting devices are removed.

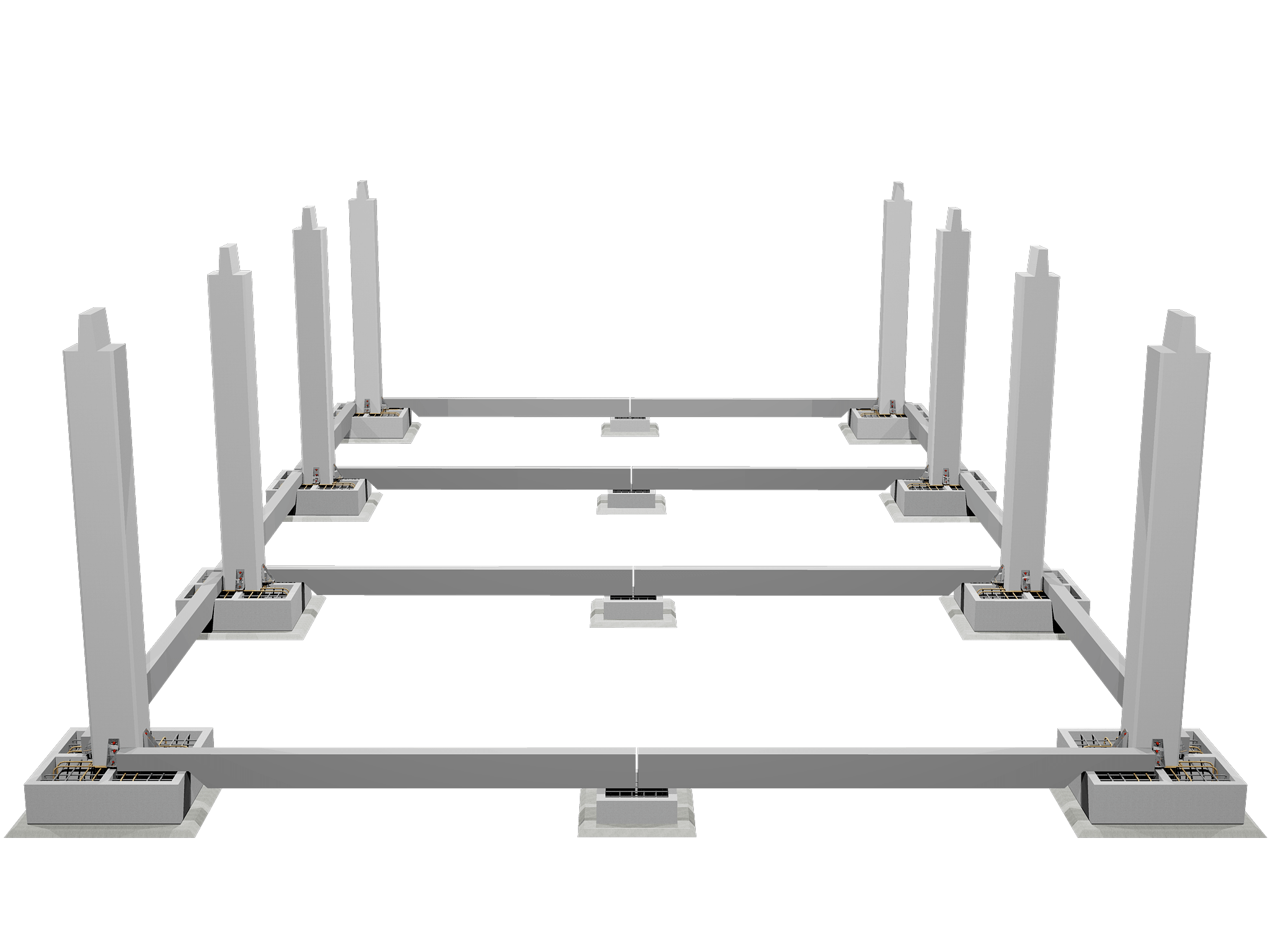

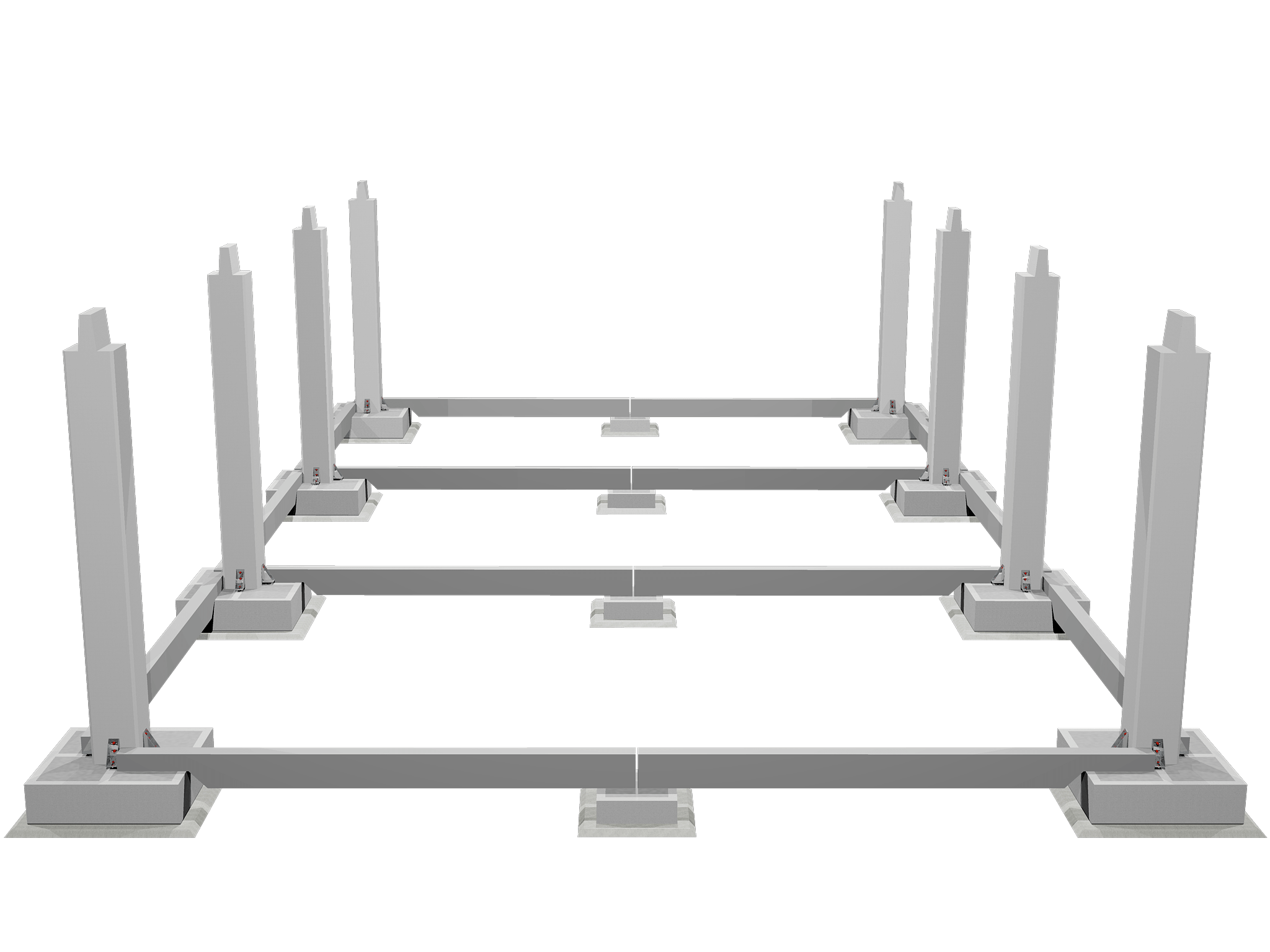

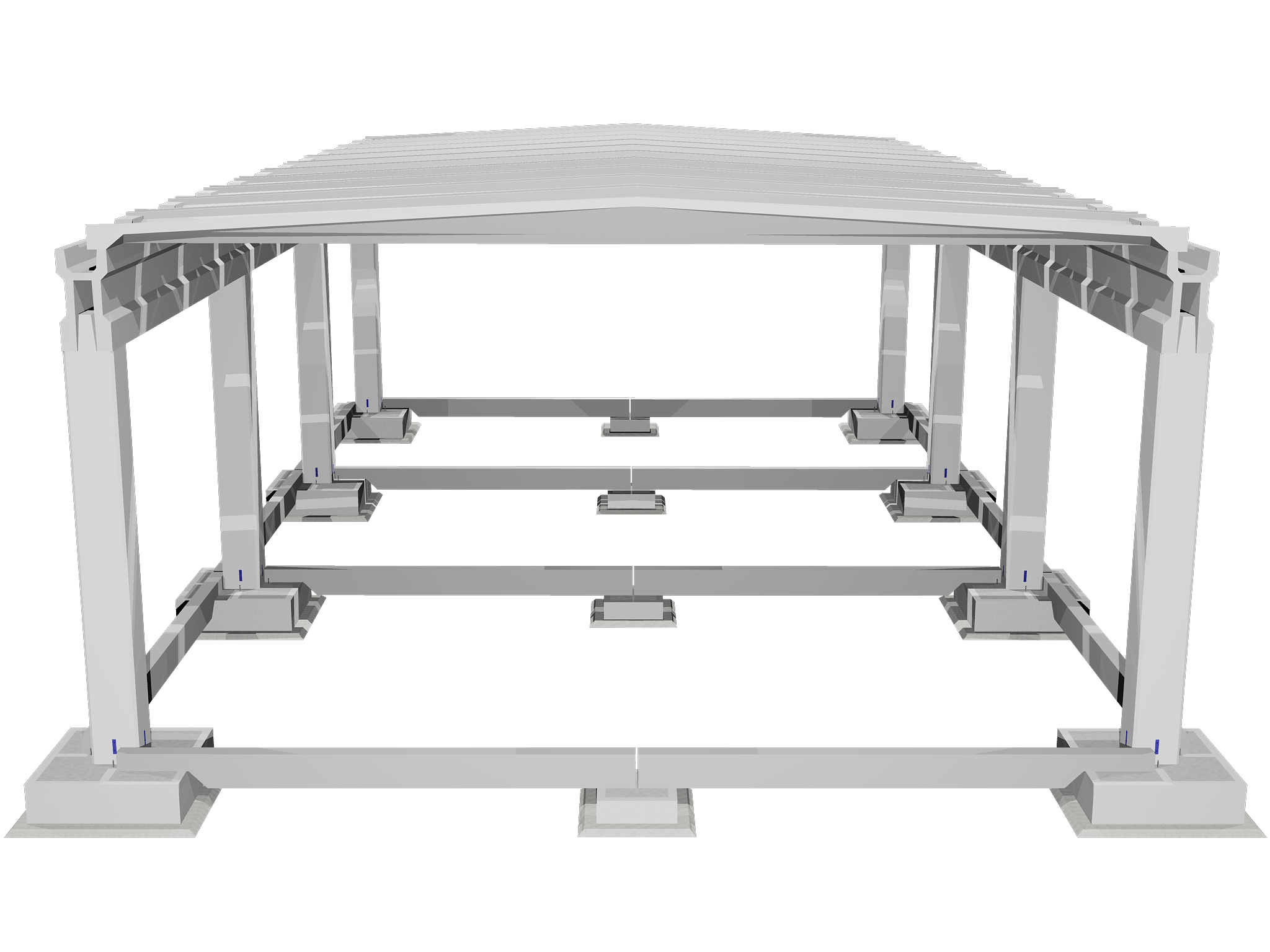

CONNECTING BEAMS

The precast element has been studied technically so as to obtain a perfect connection between the Precast Foundation and any connecting beams necessary for reducing the lateral and longitudinal strain caused by seismic action on the structure. After assembling the precast columns, the connecting beams are connected to the foundations through the rebars that jut out vertically. The connecting perimeter beams of the structure will also serve as panel beams for the precast panels and will therefore be dimensioned accordingly.

In order to optimize the dimensioning of the connecting beams, little precast pads may be used in orderto support the connecting beam in the middle point. The connecting bream can be precast or cast-in situ.

CONCRETING

The work is completed with a final casting of concrete into the Precast Pads, thereby connecting columns, beams and foundations.

CONCLUSIONS

The use of the Precast Foundation eliminates all those inconveniences that crop up during the construction of foundations using traditional methods (for example, cast-in-place), aiming to halve the costs involved in constructing a foundation structure, greater jobsite safety for workers and a turnaround speed without precedence.

Unlike traditional systems used in the construction of foundations, the use of our product does not require the additional presence of skilled workers and auxiliary tools (formwork, boards, nails, hammers, pincers, shears, etc.).

ASSEMBLING

ADVANTAGES COMPARED TO THE TRADITIONAL SYSTEMS

- 40% saving on total work costs;

- 80% saving on skilled and qualified workers;

- 60% saving on completino times;

- 100% savings on all auxiliary materials used, such as nails, wire, wooden boards for carpentry work, form release agents etc;

- 100% savings on auxiliary tools of a dangerous nature, such as saws, metal benders, shears, hammers, pincers, angle grinder.

Our precast system turns out to be the cheapest and the most efficient technology for the construction of foundations on the international market.

ABOUT US

We have been a leader in the drafting of patents in the field of new precast elements in reinforced concrete for over fifteen years. These are characterized by their marked originality, the result of the continuous research carried out by our technical staff.

What makes our name synonymous of reliability and trustworthiness is the essentiality of the values on which we base our productive experience, above all, the ability to find solutions for the customer’s every need, thanks to the expert and well-qualified support of technicians, architects and engineers who work every day in the field of research and innovation to offer solutions that are increasingly advanced and creative.

Copyright © 2008 - 2023 Monachino Technology

All rights reserved