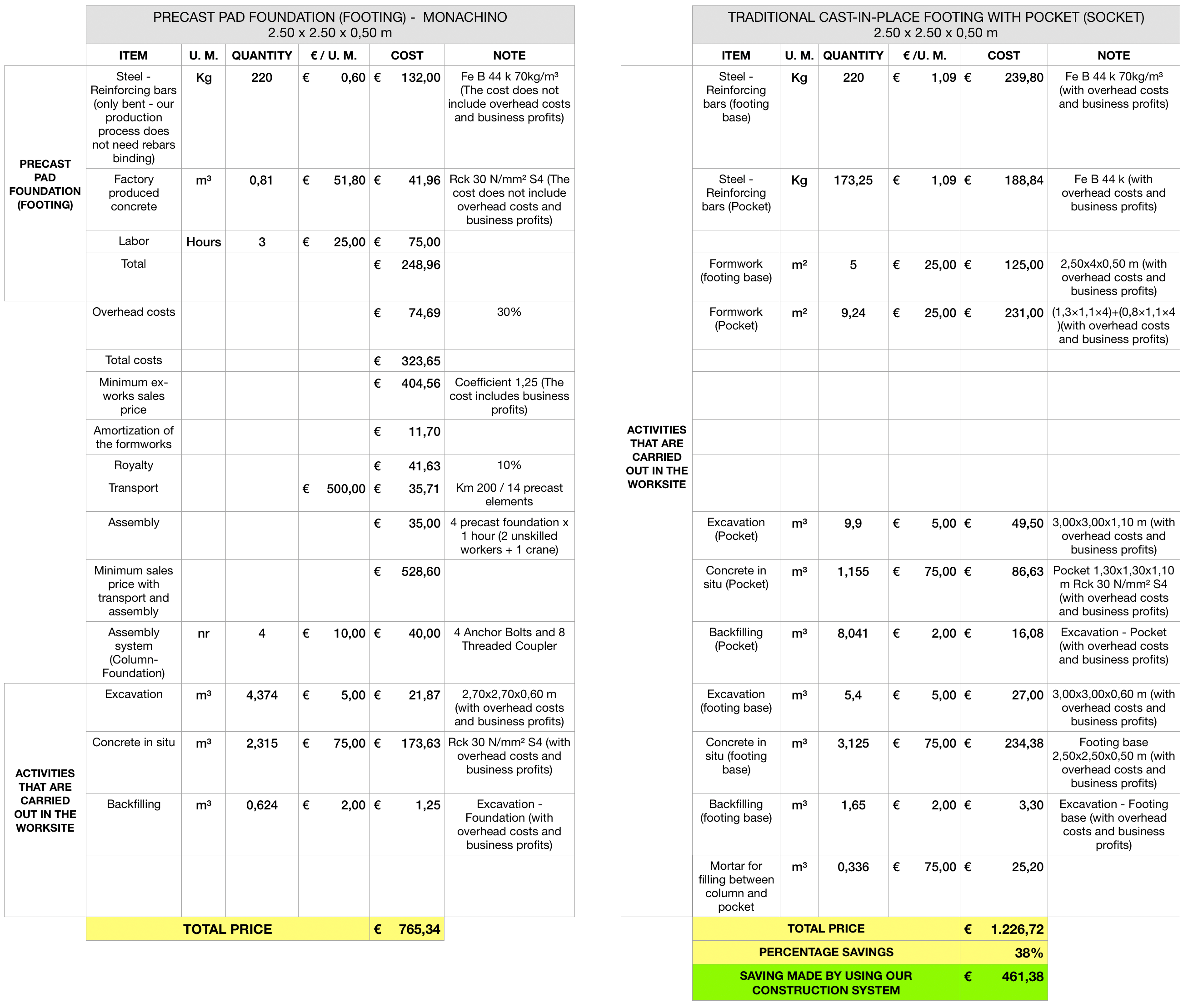

Cost analysis

PRECAST PAD FOUNDATION VS TRADITIONAL SYSTEMS

2.50 X 2.50 X 0.50 m

CONSTRUCTION SYSTEMS COMPARISON

Precast PAD Foundation VS Traditional cast-in-place footing and pocket

ADVANTAGES OVER TRADITIONAL

CAST-IN-PLACE FOOTING WITH POCKET

1. 38% savings on total work costs;

2. No skilled workers on construction site;

3. 60% savings on completion times;

4. No (precast/cast-in-place) pocket;

5. No formwork on construction site;

6. Suitable for any shape/size of column (round, square etc.)

7. 20% savings on construction excavation;

8. 20% savings on Backfilling;

9. No tools on construction site (boards, nails, hammers, pincers, shears, etc.);

10. Safer process for workers.

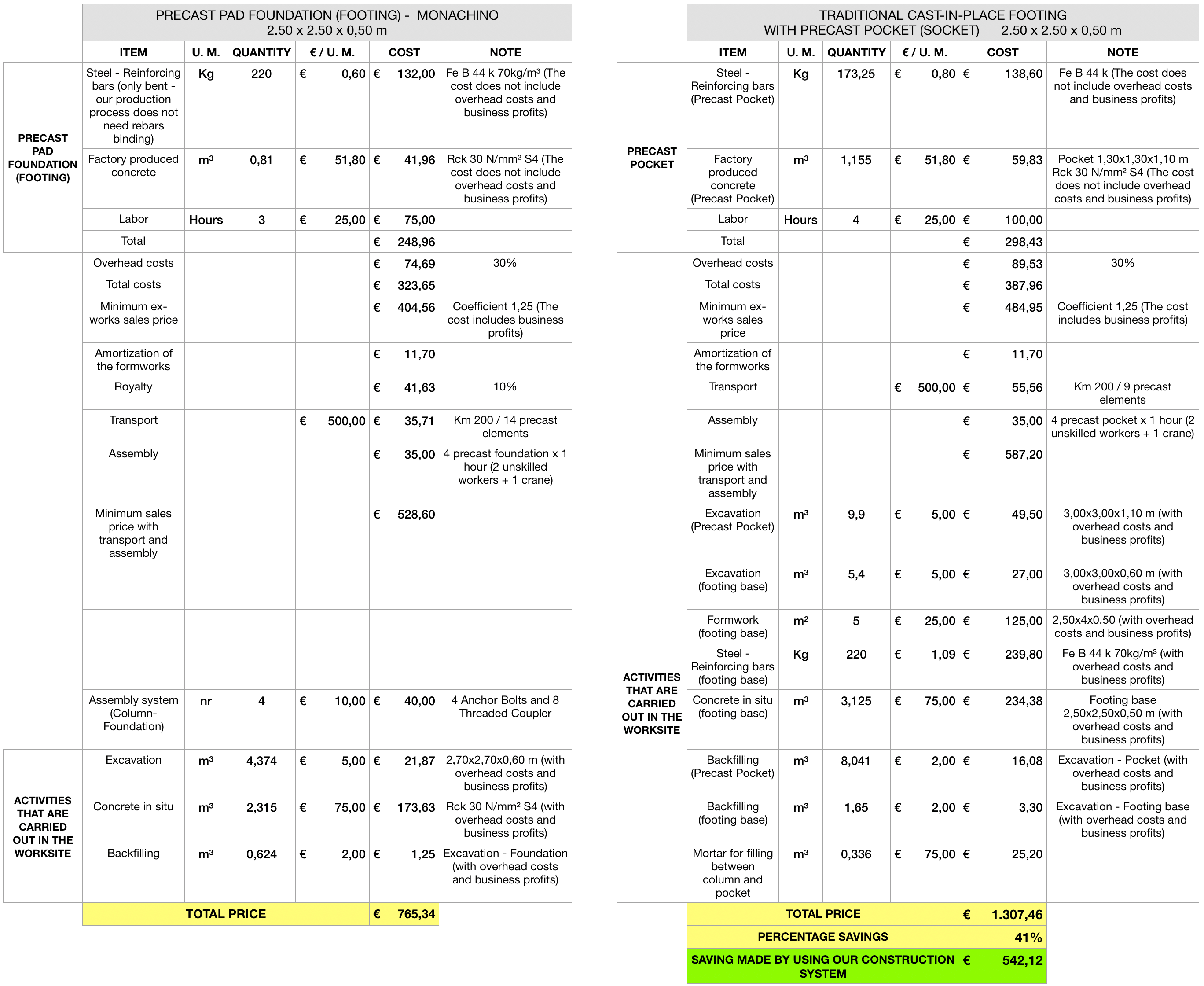

CONSTRUCTION SYSTEMS COMPARISON

Precast PAD Foundation VS Traditional cast-in-place footing and precast pocket

ADVANTAGES OVER TRADITIONAL CAST-IN-

PLACE FOOTING WITH PRECAST POCKET

1. 41% savings on total work costs;

2. No skilled workers on construction site;

3. 60% savings on completion times;

4. No (precast/cast-in-place) pocket;

5. No formwork on construction site;

6. Suitable for any shape/size of column (round, square etc.)

7. 20% savings on construction excavation;

8. 20% savings on Backfilling;

9. No tools on construction site (boards, nails, hammers, pincers, shears, etc.);

10. Safer process for workers.

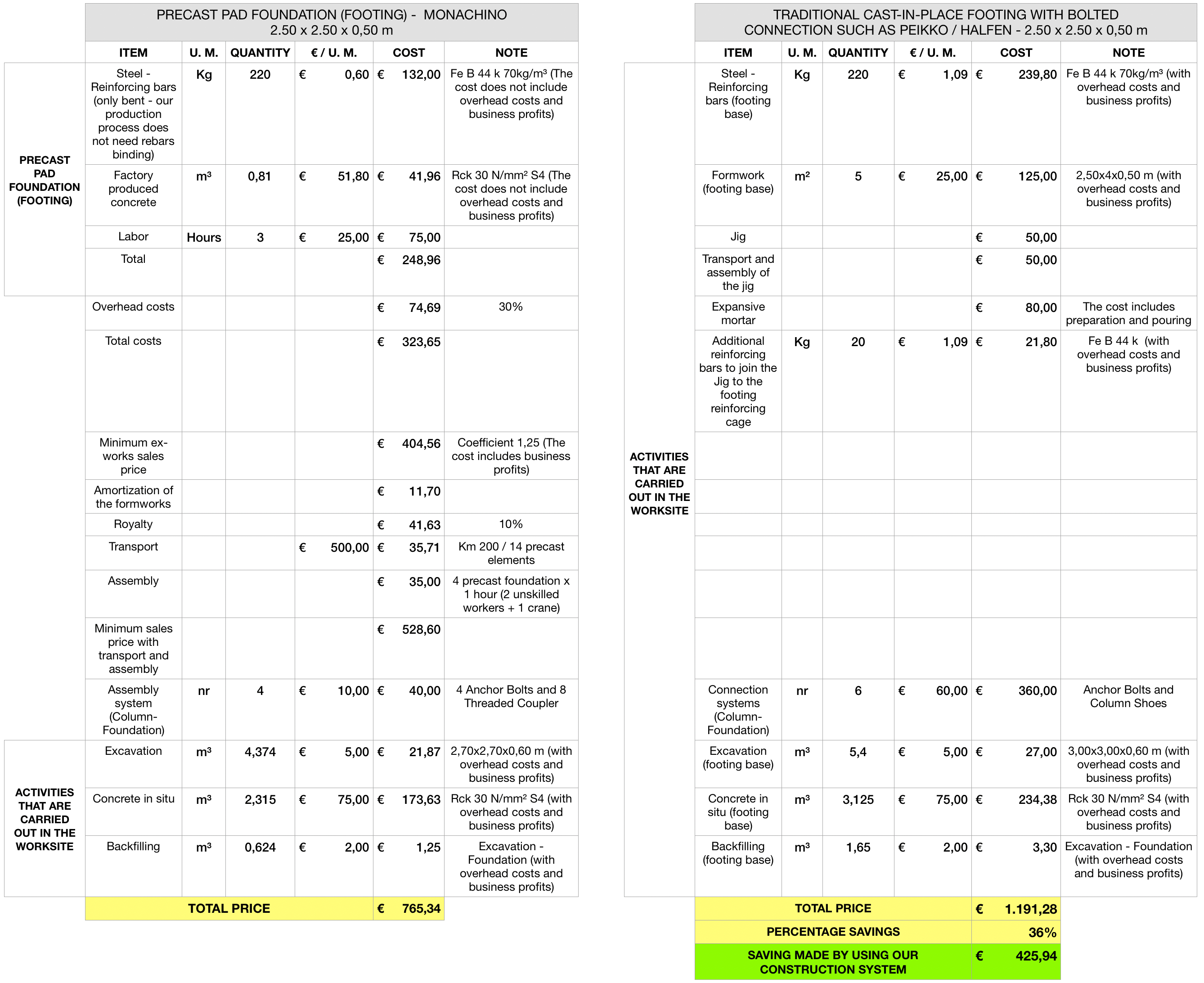

CONSTRUCTION SYSTEMS COMPARISON

Precast PAD Foundation VS Traditional cast-in-place footing with connection systems such as PEIKKO or HALFEN

ADVANTAGES OVER TRADITIONAL CAST-IN-PLACE FOOTING WITH CONNECTION SYSTEMS SUCH AS PEIKKO OR HALFEN

1. 36% savings on total work costs;

2. No skilled workers on construction site;

3. 60% savings on completion times;

4. No Column Shoes for bolted connections;

5. No Anchor bolts for bolted connections;

6. No Jig for Anchor bolts;

7. Savings on transport and assembly of the jig;

8. No adjustment of the jig;

9. No fixing of the jig;

10. No expansive mortar;

11. No formwork on construction site;

12. 20% savings on construction excavation;

13. 20% savings on Backfilling;

14. No tools on construction site (boards, nails, hammers, pincers, shears, etc.);

15. Safer process for workers.

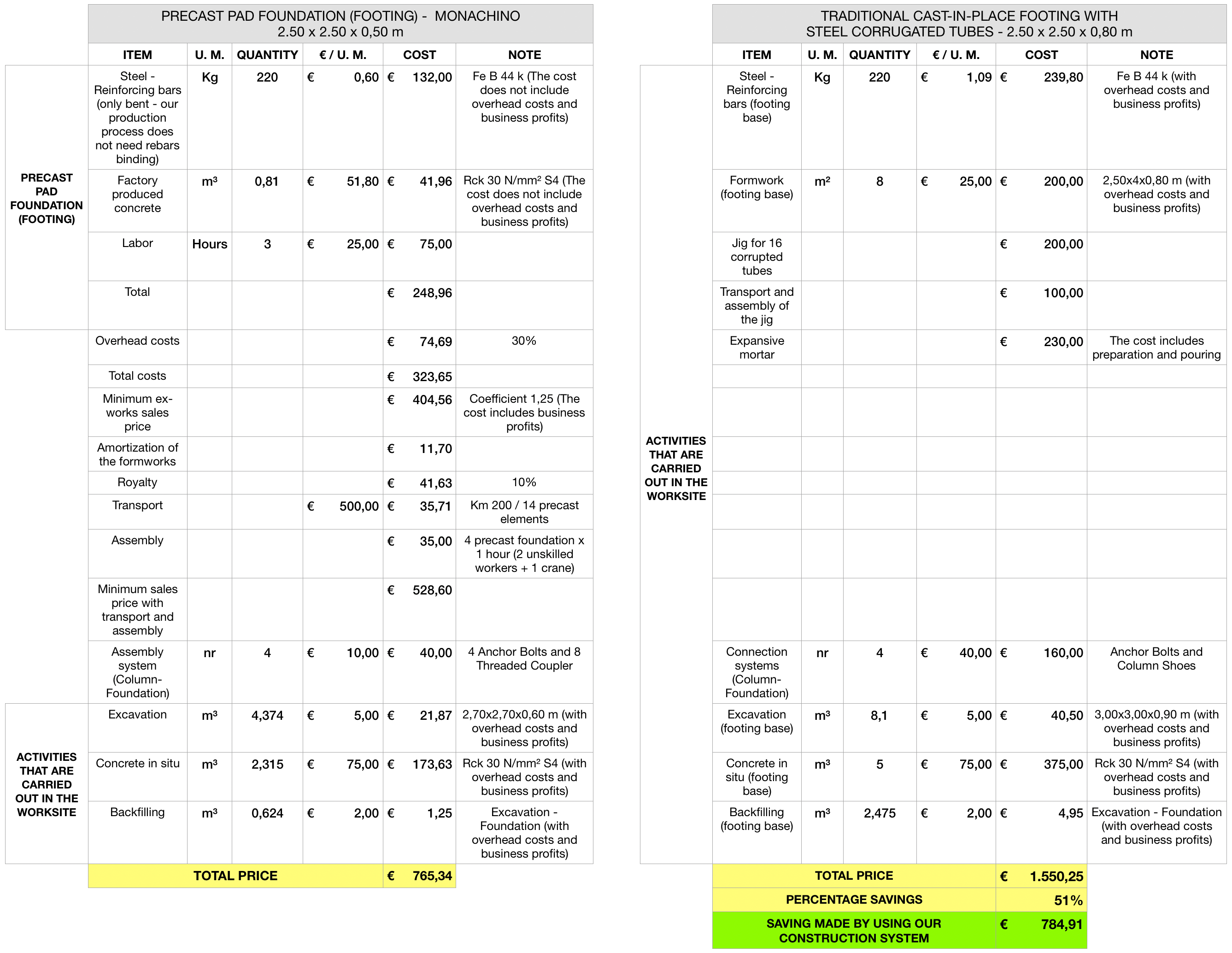

CONSTRUCTION SYSTEMS COMPARISON

Precast PAD Foundation VS Traditional cast-in-place footing with steel corrugated tubes

ADVANTAGES OVER TRADITIONAL CAST-IN-PLACE FOOTING WITH STARTER-BARS AND STEEL CORRUGATED TUBES

1. 51% savings on total work costs;

2. No skilled workers on construction site;

3. 60% savings on completion times;

4. No steel corrugated tubes;

5. No Jig for Anchor bolts;

6. Savings on transport and assembly of the jig;

7. No adjustment of the jig;

8. No fixing of the jig;

9. No expansive mortar;

10. Decrease of the footing thickness (thanks to the bent rebars that jut out from the bottom of the column).

11. No formwork on construction site;

12. 20% savings on construction excavation;

13. 20% savings on Backfilling;

14. No tools on construction site (boards, nails, hammers, pincers, shears, etc.);

15. Safer process for workers.

ABOUT US

We have been a leader in the drafting of patents in the field of new precast elements in reinforced concrete for over fifteen years. These are characterized by their marked originality, the result of the continuous research carried out by our technical staff.

What makes our name synonymous of reliability and trustworthiness is the essentiality of the values on which we base our productive experience, above all, the ability to find solutions for the customer’s every need, thanks to the expert and well-qualified support of technicians, architects and engineers who work every day in the field of research and innovation to offer solutions that are increasingly advanced and creative.

Copyright © 2008 - 2023 Monachino Technology

All rights reserved