PRECAST RETAINING WALL

WITH CAST IN PLACE FOUNDATION / FOOTING

Precast Retaining walls are concrete structures for retaining soil. They are made up of sequence of full-height modular panels (width 1.25 m or 2.50 m). The side facing the soil is endowed with one or more vertical stiffening counterforts wich extend from the base to the top of the wall.

They are placed on a underpinning slab which has been cast-in-place beforehand and whose depth is between 15-20 cm. It is then anchored through the casting of the foundation (shallow or deep, with the construction of piles or micro-piles, if the terrain requires them).

The Precast Retaining Walls are produced in four different types: with fair-faced concrete, covered with local stone, stone-grass or concrete-grass. The precast elements can be used for the construction of retaining walls for embankments, counterscarp walls, bridge abutments, abutments for artificial tunnels and noise barriers.

Both the precast elements and their highly automatized production techniques are protected by industrial patents and are perfectly suitable for any kind of soil pressure, be it low, medium or high. The wall facing can be made perpendicular to the laid substructure or inclined between 0% - 15%. Placement is very quick and produces a structure which is ready to be filled.

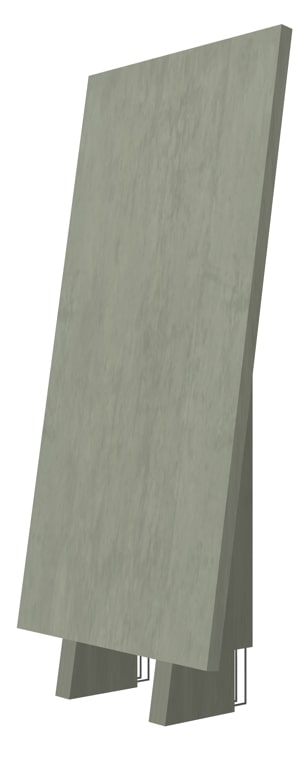

Fair-faced concrete Wall

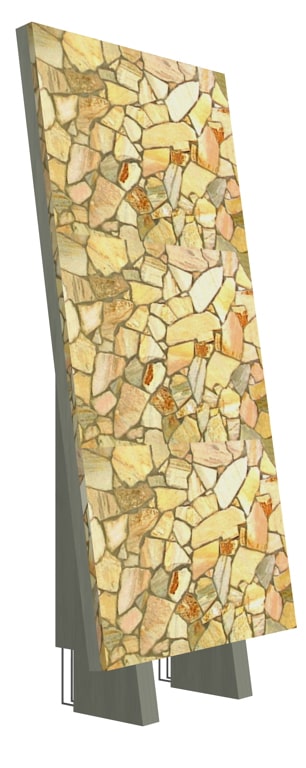

Wall covered with local stone

Stone-Grass Wall

ITEM SPECIFICATIONS

Precast Concrete Retaining Wall, factor y produced certified or controlled series products supplied with a suitable foundation to be paid separately, made up of vertical or sloping panels in vibrated concrete with stiffening counterforts on the side facing the soil which go from bottom to top, from which jut out the rebars incorporated in the foundation; the visible part can be covered with a natural or artificial stone facing which blends in with the surrounding ecosystem to safeguard the environmental impact.

The wall can be endowed with horizontal self-draining flowerbeds so that vegetation may easily grow to allow the wall to blend in better with the surrounding environment.

The wall is sized according to the current regulations regarding the verification of sliding, toppling and the maximum load of the foundation-wall-soil structure and according to current regulations regarding works carried out in reinforced concrete and, where necessary, according to current anti-seismic regulations.

FAIR-FACED CONCRETE

The facing of the Precast Retaining Wall is made up of a vertical or sloping wall of varying height with two stiffening counterforts under which can be seen the jutting out rebars which are to be incorporated in the foundation.

COVERED WITH LOCAL STONE

This option stems from the need to safeguard the environment, actually the Precast Retaining Wall can also be supplied in ecological version with precast panel covered with local stone or in any other ecological material which can be in harmony with the surrounding environment.

_

STONE-GRASS / CONCRETE-GRASS

The patent is the result of the need to protect the environment and maintain its balance. As well as having stone facing if required, this version of the Precast Wall has horizontal flowerbeds so that vegetation may easily grow to allow the wall to blend in better with the surrounding environment. The color of the facing, together with the green of the vegetation, is perfectly suitable for any natural environment.

ASSEMBLY PHASES FOR RETAINING WALLS ON SHALLOW FOUNDATION

ABOUT US

We have been a leader in the drafting of patents in the field of new precast elements in reinforced concrete for over fifteen years. These are characterized by their marked originality, the result of the continuous research carried out by our technical staff.

What makes our name synonymous of reliability and trustworthiness is the essentiality of the values on which we base our productive experience, above all, the ability to find solutions for the customer’s every need, thanks to the expert and well-qualified support of technicians, architects and engineers who work every day in the field of research and innovation to offer solutions that are increasingly advanced and creative.

Copyright © 2008 - 2023 Monachino Technology

All rights reserved